3D Scanner System Solution Based on FET3576-C Embedded Board

3D scanning, an integrated technology of optics, mechanics, electronics, and computing, captures 3D coordinates and color information of object surfaces through non-contact measurement, generating high-precision 3D models. In game development, 3D scanners have significantly enhanced the realism and detail richness of game scenes, characters, and objects.

The production team of the popular game "Black Myth: Wukong" spent a year using 3D scanning to create precise 3D models of real Buddhist statues, temples, and rocks across China. These models not only provide rich materials and inspiration for game designers but also ensure the authenticity and detail richness of game scenes. By capturing real-world 3D data, every detail in the game accurately reproduces historical features, enhancing the game's cultural depth and artistic value.

Not only in the gaming field, but 3D scanning systems, with their high precision, non-contact measurement, and digitization characteristics, can also contribute to the preservation and restoration of cultural relics. The fire at Notre-Dame Cathedral in 2019 attracted global attention. Prior to this, Notre-Dame Cathedral had already undergone comprehensive data recording using 3D scanning technology. This allows experts to use this data to carry out precise repair work after the fire. In addition, it can also be widely used in surveying and mapping engineering, industrial manufacturing, architectural design, education and scientific research and many other industries.

The 3D scanner, as the core component, is responsible for data acquisition and conversion. It consists of a probe, lens, and camera. The probe collects surface patterns without contact, the lens adjusts the probe position and viewing angle, and the camera converts captured images into digital signals for further processing like denoising, stitching, and optimization.

Hardware implementation faces several challenges:

- Complex data processing: Limited by onsite conditions during data collection, processing can be complex, requiring extended post-processing like noise removal and mesh reconstruction, demanding high-performance hardware.

- Compatibility issues: Incompatible hardware and software designs for point cloud data processing across different manufacturers hinder resource sharing and conversion, increasing learning and technical difficulties for users.

- Environmental sensitivity: Lasers and optical systems are sensitive to temperature changes, requiring frequent calibration and affecting efficiency. External factors like temperature, humidity, and vibration can also impact measurement accuracy, necessitating strict environmental control.

- High cost: The hardware cost of 3D scanners is often high, potentially leading to increased product prices and affecting market competitiveness.

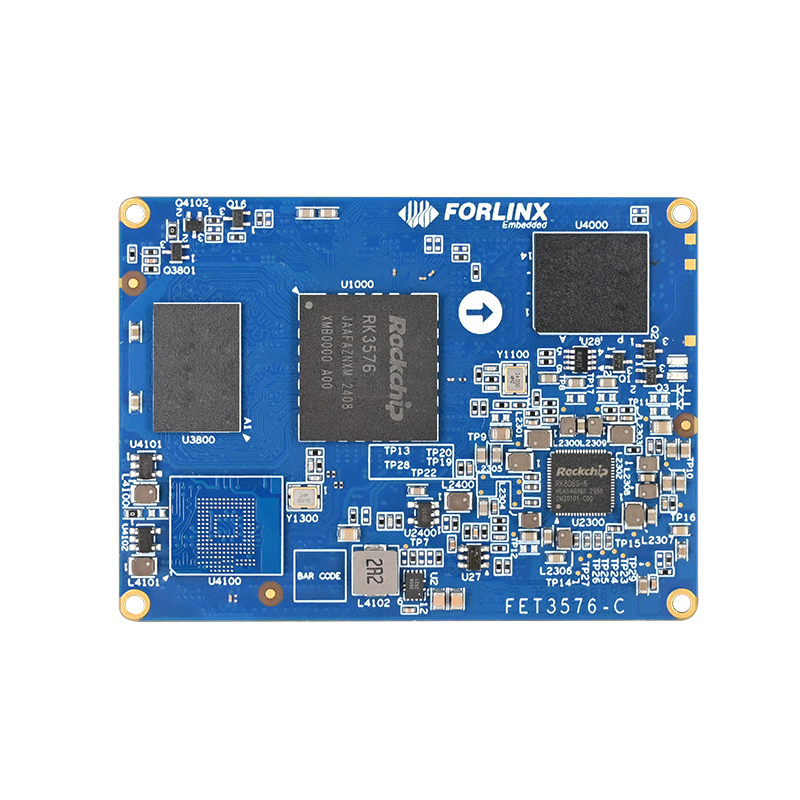

Forlinx Embedded recommends using the FET3576-C embedded board as the main controller for 3D scanners. Based on the RK3576 processor, the FET3576-C is a high-performance, low-power, feature-rich, cost-effective solution tailored for AIoT and industrial markets. It integrates four ARM Cortex-A72 and four ARM Cortex-A53 high-performance cores, with a 6TOPS powerful NPU supporting various operations and deep learning frameworks.

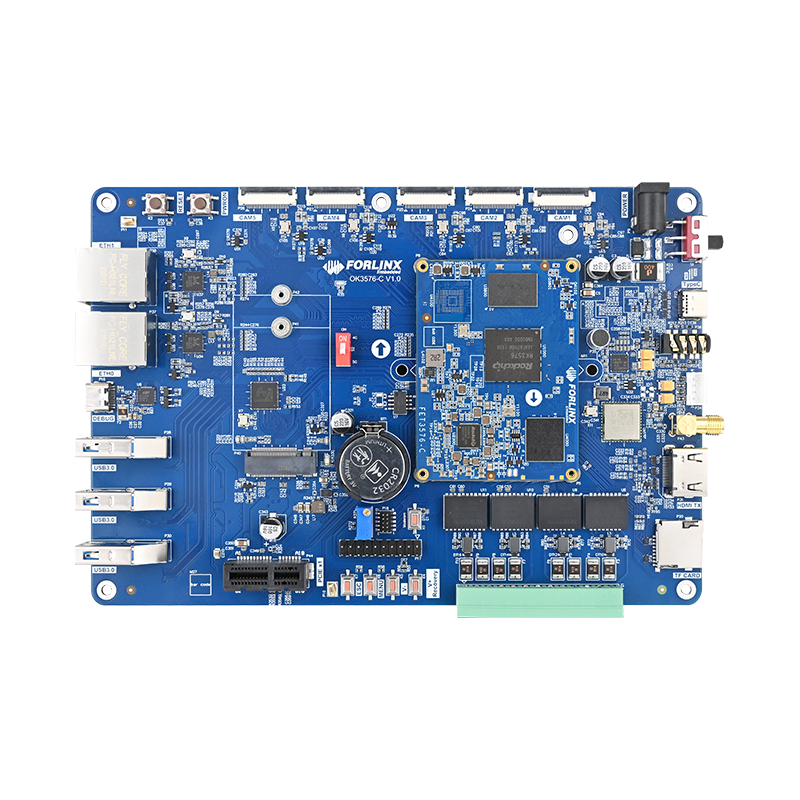

(1)Versatile Interfaces

With GPIO, UART, SPI, and other communication interfaces, the FET3576-C precisely controls scanning parameters (e.g., scanning speed, resolution) and sensor states (e.g., laser emitter, camera shutter), enhancing scanning efficiency and quality

(2)Data Processing Hub

As the system's ''brain,'' the FET3576-C processes raw data like laser point clouds and images, ensuring accurate and complete 3D models through filtering, denoising, registration, and fusion.

(3)Intelligent Optimization

6TOPS NPU enables intelligent analysis of scanned data, automatically identifying and optimizing issues like flaws and holes in models, further enhancing their fineness and realism.

(4)Data Transmission and Storage

Supporting up to 4GB LPDDR4 RAM and 32GB eMMC storage, the FET3576-C securely and efficiently stores scan data locally. Additionally, it supports dual Gigabit Ethernet and Wi-Fi for real-time data transmission and remote access.

(5)Product Stability

With a board-to-board connection design, the FET3576-C facilitates easy installation and maintenance. It has undergone rigorous industrial environment testing, providing excellent stability, and a 10-15 year longevity ensures long-term supply reliability for customer products.

Forlinx Embedded FET3576-C embedded board plays a crucial role in 3D scanning systems. As the main controller, it leverages its powerful data processing capabilities and rich interface resources to enable end-to-end control from data acquisition to model output, providing a solid technical foundation for building high-precision and realistic 3D models.