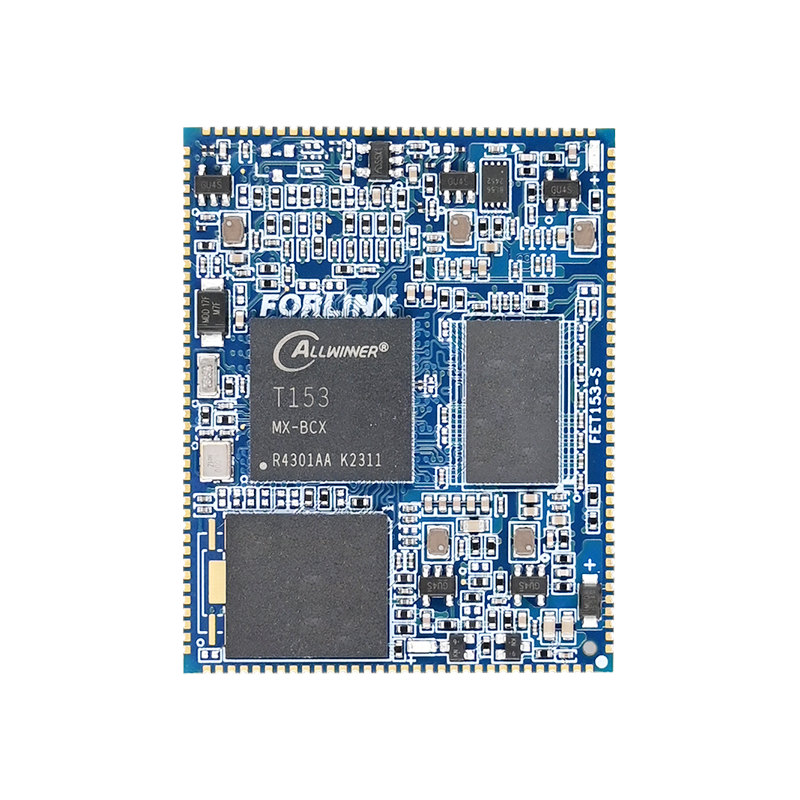

FET153-S SoM: Empowering PLC Intelligent Control Upgrade with Multi-core Performance and High Reliability

In the era of Industry 4.0 and intelligent manufacturing, Programmable Logic Controllers (PLCs) serve as the core equipment for industrial automation and are encountering various challenges in enhancing performance and fulfilling high-reliability standards. The FET153-S SoM, launched by Forlinx Embedded, offers a new solution for PLC equipment due to the inherent advantages of the T153 industrial processor, including multi-core heterogeneous computing, comprehensive interface coverage, and industrial reliability design.

Multi-core Heterogeneous Architecture

Solving the Contradiction Between Real-time Control and Efficient Computing in PLC

Traditional PLC main control primarily relies on single-core architecture, which can lead to computing power bottlenecks when handling complex logic controls, such as motor speed regulation and real-time sensor acquisition, as well as high-throughput data tasks like multi-port communication and equipment status monitoring.

The Allwinner T153 processor, used in Forlinx Embedded's FET153-S SoM, features a multi-core heterogeneous architecture consisting of a 4-core Cortex-A7 and an independent RISC-V E907. This design effectively addresses the dual requirements of programmable logic controllers (PLC).

The 4 x Cortex-A7 cores are responsible for the communication management, data storage, and complex algorithm operations of the PLC. For example, on the welding production line in automobile manufacturing, they can process the status data from multiple welding robots and the instructions from the upper-level computer, realizing real-time data analysis and response.

The RISC-V E907 core focuses on real-time control tasks, such as millisecond/microsecond-level logic operations, high-speed I/O point scanning, and interrupt handling in PLCs. In automated assembly line scenarios, strict synchronization between multiple sensors and actuators can be ensured, preventing declines in production rhythm or errors in product processing caused by delays in the scanning cycle.

Full-Scenario Interface Coverage

Meets the Complex Industrial Interconnection Needs of PLC

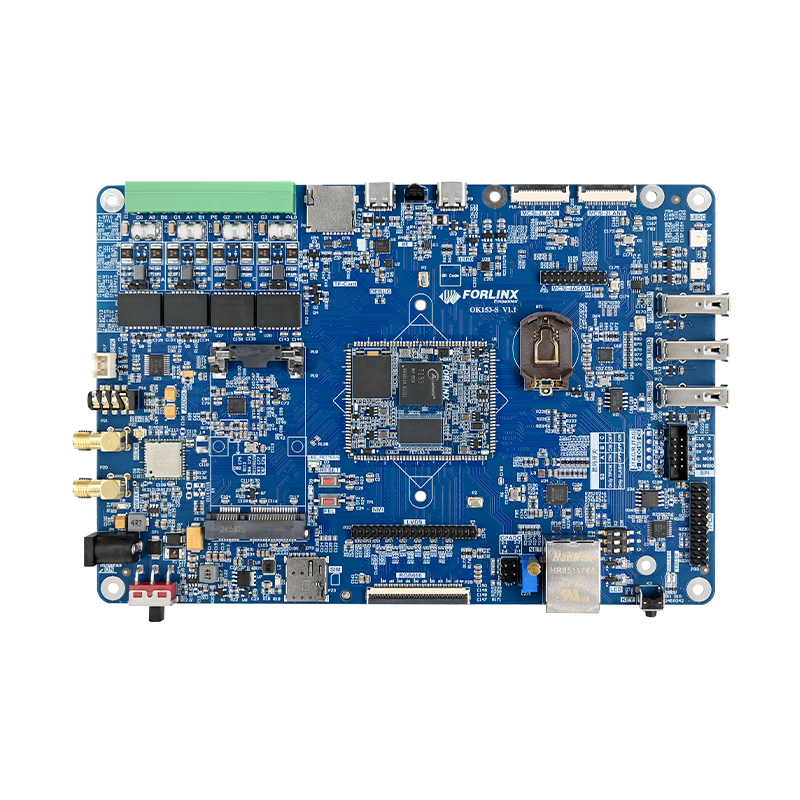

As the ''nerve center'' of the industrial field, PLCs need to connect various types of devices such as sensors, actuators, and Human-Machine Interfaces (HMIs). Forlinx FET153-S SoM exposes all CPU pins through a stamp hole and LGA connector, allowing high-bandwidth communication and flexible expansion interfaces.

Industrial Network Integration: It includes 3 x Gigabit Ethernet ports (supporting RMII/RGMII) and 2 x CAN-FD interfaces, compatible with CAN 2.0A/B. This allows for "industrial switch-level" networking without the need for additional expansion chips. For instance, a power monitoring terminal can simultaneously connect smart meters, circuit breakers, and an upper-level computer.

Sensor and Actuator Connection: It features 24 x 12-bit GPADC, 30 x PWM channels, and 10 x UART channels, which can accurately collect analog signals such as temperature and pressure, as well as drive equipment like servo motors and frequency converters. In the photovoltaic inverter scenario, the GPADC can monitor the DC-side voltage in real-time, with a PWM output frequency ranging from 0 to 24MHz or 0 to 100MHz, ensuring efficient execution of the MPPT algorithm.

Display and Interaction Support: It integrates MIPI-DSI, LVDS, and RGB interfaces, supporting a maximum display resolution of 1920×1200@60fps, and can be adapted to industrial touch screens and HMI devices. Meanwhile, the 4-lane MIPI-CSI interface supports the access of dual cameras, providing a hardware foundation for machine vision inspection.

Industrial-grade Reliability

Stable Operation in Harsh and Complex Environments

In the harsh industrial environment, PLC needs to withstand multiple tests such as high and low temperature, vibration, electromagnetic interference and so on. The FET153-S SoM ensures long-term stable operation through the following designs:

Stringent Environmental Testing: It has successfully passed the tests in Forlinx Embedded's self-built standard laboratory, which include physical environment tests, electromagnetic compatibility tests, and stability tests.

Long-term Supply Guarantee: In response to Allwinner's commitment to ''over 10-year longevity for industrial chips,'' it ensures a stable supply for 10 to 15 years, preventing the costs associated with equipment obsolescence due to chip discontinuation.

Safety Compliance and Efficient Development

Accelerates the Implementation of PLC Projects

The FET153-S SoM not only offers hardware performance but also reduces the threshold of PLC development through security protection, software ecosystem, and comprehensive services:

Safety Compliance: It has a built-in TrustZone and Secure Boot mechanism to prevent firmware tampering. At the same time, it integrates a hardware encryption acceleration unit, supporting the encryption of power data and the protection of sensitive information in financial industrial terminals.

Software and Documentation: It supports Linux 5.10 and provides a full set of technical documentation such as the carrier board schematic diagram, pin multiplexing table, and test routines. Developers can quickly complete driver transplantation and application development.

The FET153-S SoM offers a cost-effective solution for PLC devices with its unique advantages of multi-core computing power, full interfaces, and industrial-grade reliability. It not only meets the strict requirements of the industrial field for performance, connectivity, and stability but also helps customers accelerate project implementation through safety design and comprehensive development support. As intelligent manufacturing and industrial automation continue to advance, the FET153-S SoM has become a preferred option in the realm of industrial PLC master controllers.