In-depth Explanation of Allwinner T153 Processor: A Cost-effective Industrial Chip

On September 24, 2025, Allwinner Technology successfully held the ''Allwinner Industrial Ecosystem Seminar and T153 Chip Release Conference'' in Shanghai, officially launching the T153 processor. Allwinner positions the T153 as a ''cost-effective industrial chip'', aiming to bring a ''smart brain'' with sufficient computing power, high scalability, a comprehensive software ecosystem, and a wide range of application fields to the intelligent industrial sector.

So, how does the T153 shape these advantages? In this article, let’s take a closer look at this chip.

1. Multi-core Heterogeneous Architecture: Balancing High Performance and Real-time Capability

The Allwinner T153 processor uses a unique multi-core heterogeneous design. It integrates a quad-core Arm Cortex-A7 high-performance CPU with a main frequency of up to 1.6 GHz, and is also equipped with a single-core RISC-V XuanTie E907 real-time coprocessor with a main frequency of 600 MHz. This architecture cleverly balances the computing performance and real-time control requirements, achieving both:

- Cortex-A7 Cores: Responsible for handling complex upper-layer applications, data communication, and human-machine interaction tasks, providing powerful general-purpose computing capabilities;

- RISC-V E907 Core: Focuses on control tasks with high real-time requirements, such as motor control, sensor data acquisition, and real-time response, significantly reducing the load on the main core.

Compared with traditional industrial MCUs/MPUs, the T153 not only provides stronger computing power but also achieves true high-performance and real-time capabilities through its heterogeneous architecture, offering a more ideal hardware platform for modern industrial automation equipment.

2. Rich Interfaces: Meeting Diverse Industrial Scenario Requirements

It fully considers the actual needs of industrial applications in its interface configuration, providing a very rich set of interfaces:

(1) Network and Industrial Bus Interfaces

- 3 x Gigabit Ethernet: Support multi-node network deployment, meeting the high-throughput network connection requirements of industrial equipment;

- 2 x CAN-FD Interfaces: Support data transfer of up to 64 bytes, are compatible with the CAN 2.0A/2.0B standards, and are suitable for high-reliability data interaction requirements in fields such as automotive and power;

- 1 x LocalBus Parallel Bus: Supports 8/16/32-bit widths, with a maximum interface speed of 150 MHz@16 bits and 100 MHz@32 bits, facilitating high-speed data exchange with peripherals such as FPGAs.

(2) General Peripheral Interfaces

- 10 x UART Serial Ports: Meet the connection requirements of multi-serial-port devices;

- 30 x PWM Interfaces: Support various motor control and power management scenarios;

- 24 x GPADC: With a 12-bit sampling resolution and a maximum sampling rate of 1 MHz, support analog signal acquisition;

- 6 x TWI Interfaces: Compatible with the I2C standard, support connection of various sensors.

- 4 x SPI Interfaces: With a maximum clock frequency of 100 MHz;

- 14 x GPIO: Provide sufficient expansion capabilities.

These interfaces provide flexibility for diverse applications, enabling convenient integration and expansion of automation systems.

(3) Display and Image Processing Capabilities

The T153 integrates a powerful image processing and display engine, providing a good visual experience for industrial human-machine interface (HMI) applications:

- Display Capability: Supports three display interfaces (RGB, LVDS, MIPI DSI) in a multiplexed mode, with a maximum resolution of 1920×1200@60fps, which can be adapted to industrial touch screens and other devices;

- Image Processing: Integrates an ISP image signal processor, supports two-channel sensor input, with a processing capacity of 1M@30 fps online or 2M@30 fps offline;

- Graphics Acceleration: Built-in G2D graphics acceleration unit, supports smooth rendering of interfaces.

3. Industrial-grade Reliable Design for Comprehensive Protection

The T153 processor closely addresses the pain points of industrial scenarios in its parameter design. Through wide-temperature operation, high integration, and security mechanisms, it ensures stable operation in harsh environments.

- Wide-temperature Operation: Supports an operating temperature range of-40°C to + 85°C, adapting to various harsh industrial environments;

- Long Lifecycle: Provides a continuous supply guarantee for 10-15 years, meeting the long-service-life requirements of industrial equipment and providing stable support for long-term industrial projects;

- Security Features: Supports secure boot and encryption algorithm IP, meeting the requirements of industrial security certifications such as IEC-60730 Class-B and PSA L1.

4. Software Ecosystem and Development Support

At the software level, the T153 supports the AMP multi-core heterogeneous system and can run multiple operating systems such as Tina Linux, RTOS, and Baremetal simultaneously. This flexible software architecture allows developers to allocate tasks according to actual needs, meeting the high-real-time requirements in fields such as industrial automation and forming a complete software ecosystem for the intelligent industrial sector.

Allwinner Technology also provides a complete software development kit to help customers quickly productize their solutions. In addition, software ecosystem partners such as CODESYS and OneOS provide industrial operating systems and software platforms, forming a complete development ecosystem from the chip to the system.

5. Rich Application Scenarios for Comprehensive Empowerment of Intelligent Industry

The multi-core heterogeneous architecture and abundant interfaces of the T153 processor make it an ideal choice for fields such as industrial automation, power energy, and robotics. Here are some simple examples of applications.

-

Industrial Control:

- PLC (Programmable Logic Controller): The Cortex-A7 core handles logical operations and data communication, while the RISC-V core realizes real-time I/O control, improving the device response speed.

-

Power Industry:

- Power Monitoring Terminal: The wide-temperature design and encryption security features are suitable for outdoor scenarios such as substations and distributed energy, ensuring the stability of data acquisition and transmission.

-

New Energy:

- Photovoltaic Inverter: Monitors the status of photovoltaic modules through the CAN-FD interface and controls power devices through the PWM interface to achieve maximum power point tracking (MPPT).

- Charging Pile: Supports connection with 4G modules and payment systems, and connects to metering modules through the LocalBus interface, improving the efficiency of charging services.

Conclusion

The brand-new T153 chip platform integrates high-performance computing, real-time control, abundant interfaces, and an open software ecosystem, laying a solid foundation from the hardware level and providing strong support for industrial intelligent manufacturing. With the continuous advancement of Industry 4.0 and intelligent manufacturing, the T153 is expected to play an important role in fields such as industrial control, power energy, and intelligent transportation, providing high-performance, high-reliability, and stable-supply chip solutions for industry customers and facilitating the intelligent upgrade of the industry!

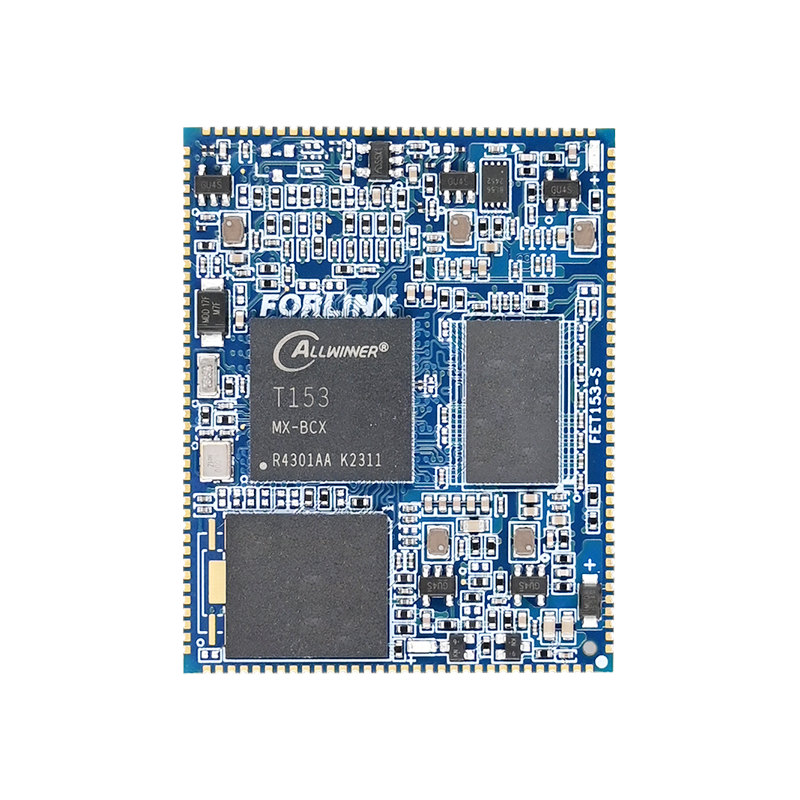

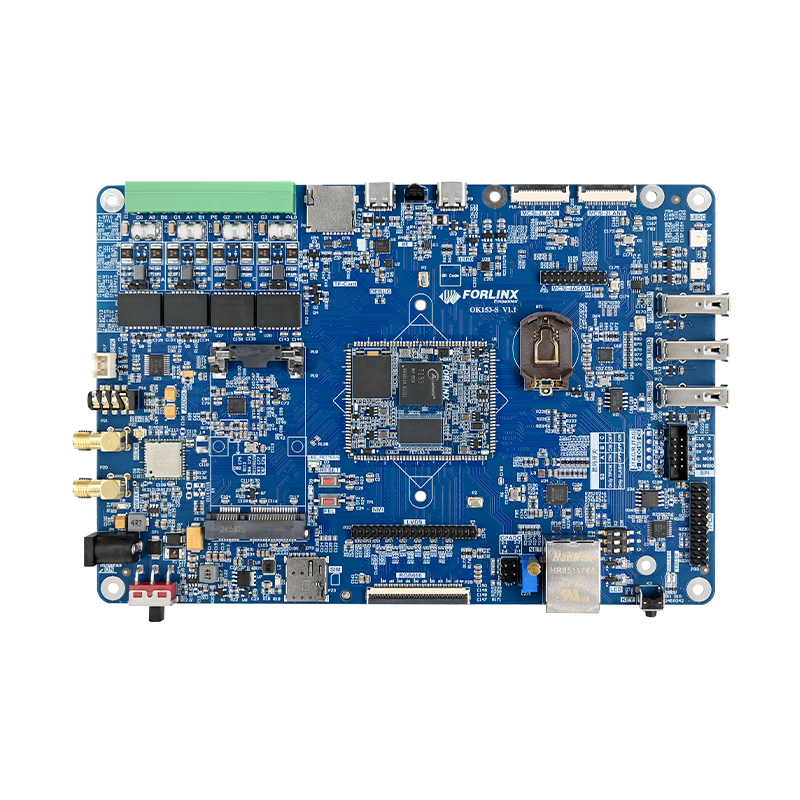

It is worth noting that Forlinx Embedded has officially released the SoM solution based on the T153 - FET153-S SoM, providing industry customers with a convenient way to quickly productize their solutions, significantly shortening the development cycle and accelerating product launch.

Note: Some of the picture content in this article is from Allwinner Technology.