Advantages of Using FETA40i-C in Laser Coding Machines

1. Introduction to Laser Coding Machines:

Laser coding machines use high-energy lasers focused directly on the surface of objects to induce physical and chemical changes, creating markings.

As the laser beam's focus moves systematically across the marking surface, controlling the laser's activation allows for the creation of specific marking patterns on the object's surface.

Laser marking offers advantages such as non-contact marking, high speed, minimal pollution, no consumable loss, and clear, permanent identification. These benefits give it a competitive edge, leading to its gradual replacement of traditional ink-jet coders.

2. Structure of Laser Coding Machines:

A laser coding machine primarily consists of the following components:

- Control System: The core component responsible for editing and processing marking content, generating marking data, transmitting it to the galvo system and laser system, and handling external input.

- Laser System: Responsible for generating and transmitting the laser to the galvo system.

- Galvo System: Quickly and precisely rotates mirrors to alter the laser beam's path, focusing it into a spot on the marking surface.

- Power Supply System: Provides power to the entire laser marking machine, including the controller, laser, and galvo system.

- Conveyor Mechanism: Moves items to be marked and uses speed measurement devices to monitor real-time item movement, feeding this data back to the control system.

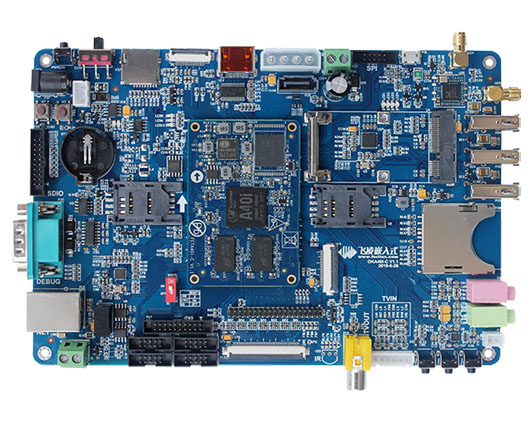

3. ARM+FPGA-Based Control System Design:

ARM processor manages the human-machine interface, complex data processing, and communication, while the FPGA handles the reception, storage, conversion of marking data, and controls the marking equipment.

The marking control is managed by the marking card, with real-time performance mainly relying on the FPGA. ARM SoM is used for interface display and higher-level computation.

4. Forlinx Solution

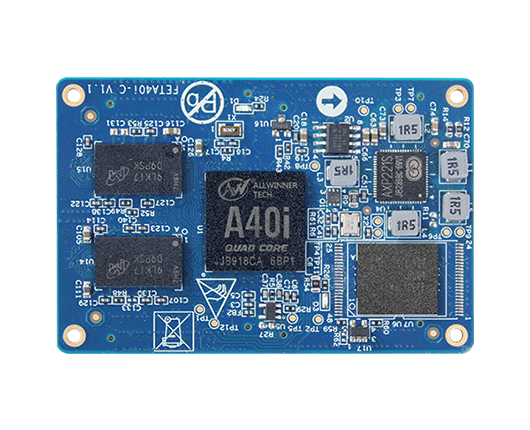

Forlinx Embedded recommends the FETA40i-C SoM as the ARM platform for laser coding machines, offering notable advantages: Notable advantages:

- High Performance Processing: The A40i platform, with its 1.2GHz high frequency, rapidly processes complex coding tasks. In laser coding machines, a high-performance processor ensures speed, precision, and efficiency in coding, with the A40i's high frequency reducing response time, enhancing productivity.

- Excellent Display Capabilities: A40i platform supports multiple display interfaces, making the coding interface more intuitive and visually appealing. A clear and user-friendly interface is crucial for operators, who can more easily view and edit coding content via a large screen, improving work efficiency.

- Robust Communication Capabilities: A40i features dual Ethernet ports and a 4G communication module, supporting various communication methods. This allows easy data transfer and communication with other devices, meeting the networking needs of modern industrial production, and facilitating future interface upgrades.

- Extensive External Expansion Interfaces: A40i platform offers numerous native external expansion interfaces, including 8 x serial ports and 3 x USB. These provide ample connection options for external devices, enabling easy integration and interaction with various peripherals.

- Industrial-Grade Stability and Reliability: A40i is an industrial-grade CPU known for its stable and reliable quality. Stability and reliability are critical in laser coding machines, ensuring long-term stable operation in harsh industrial environments, reducing failure rates, and extending equipment lifespan.

In summary, Forlinx Embedded A40i platform offers numerous advantages as the hardware control platform for laser coding machines, meeting the high-performance, high-stability, and high-reliability demands of modern industrial production.