The Design Insight of A Peritoneal Dialysis Machine Based on Forlinx T113 SoM

Product Description

The peritoneal dialysis machine is an advanced medical device designed for performing peritoneal dialysis, a treatment for acute and chronic renal failure. This process involves infusing dialysate into the patient's abdominal cavity, where the peritoneum serves as a semipermeable membrane to exchange solutes and fluids, effectively removing metabolic waste and toxins while correcting fluid and electrolyte imbalances. The device comprises a main unit, control unit, and heater, available in both powered and gravity-driven models.

This technology significantly enhances the quality of life for patients, allowing them to connect the peritoneal dialysis catheter to an automated machine before sleep. The machine performs dialysis treatments overnight, typically for 8 to 10 hours. In the morning, patients can disconnect the catheter and continue their daily activities seamlessly.

Hardware Key Components

- Central Control Unit: Manages the operation and data processing of the device. Modern systems feature intelligent controls that monitor and record real-time parameters, such as infusion volume, dwell time, drainage time, outflow volume, and dialysate temperature.

- Heater: Ensures the dialysate is warmed to the optimal temperature, improving efficiency and patient comfort.

- Power Unit: Facilitates the delivery and drainage of dialysate to and from the patient's peritoneal cavity.

- Sensors and Monitoring System: Utilizes various sensors to ensure real-time monitoring and safety of the dialysis process.

- User Interface: Provides an intuitive platform for setting parameters, monitoring status, and receiving alerts.

Main Challenges in Hardware Design

- Precise Control and Monitoring: Demands accurate control and monitoring of parameters like temperature, pressure, and flow rate, requiring high hardware accuracy and stability.

- Portability and Compact Design: Essential for home-based dialysis, necessitating a balance between size, weight, and performance.

- Safety and Reliability: Critical for medical equipment, requiring thorough consideration of electrical and mechanical safety, and prevention of cross-contamination.

- Cost-effectiveness: Balancing performance, safety, and reliability with reduced hardware costs to alleviate patient financial burdens and enhance market competitiveness.

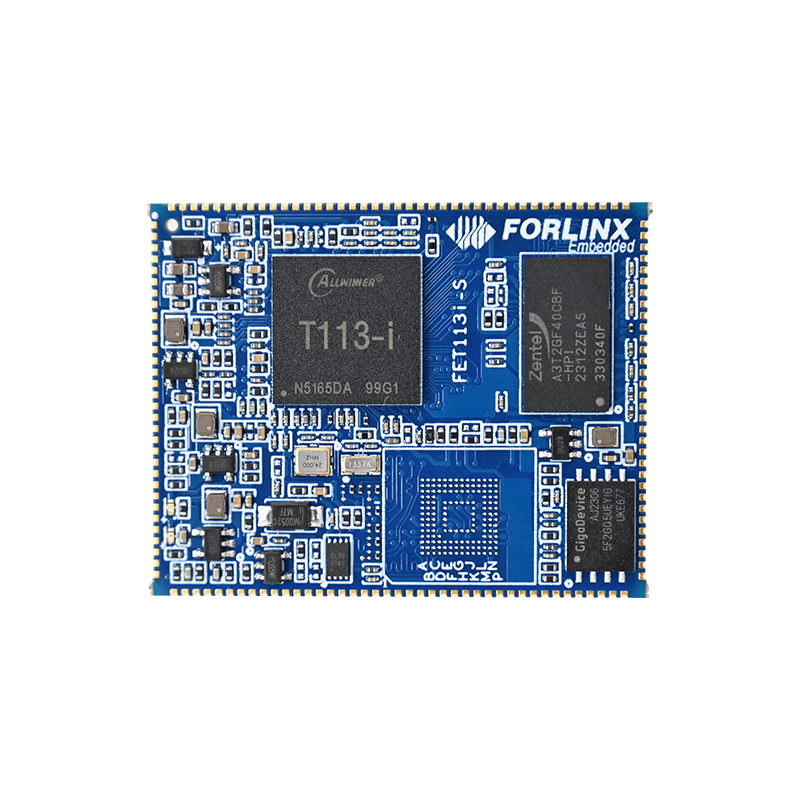

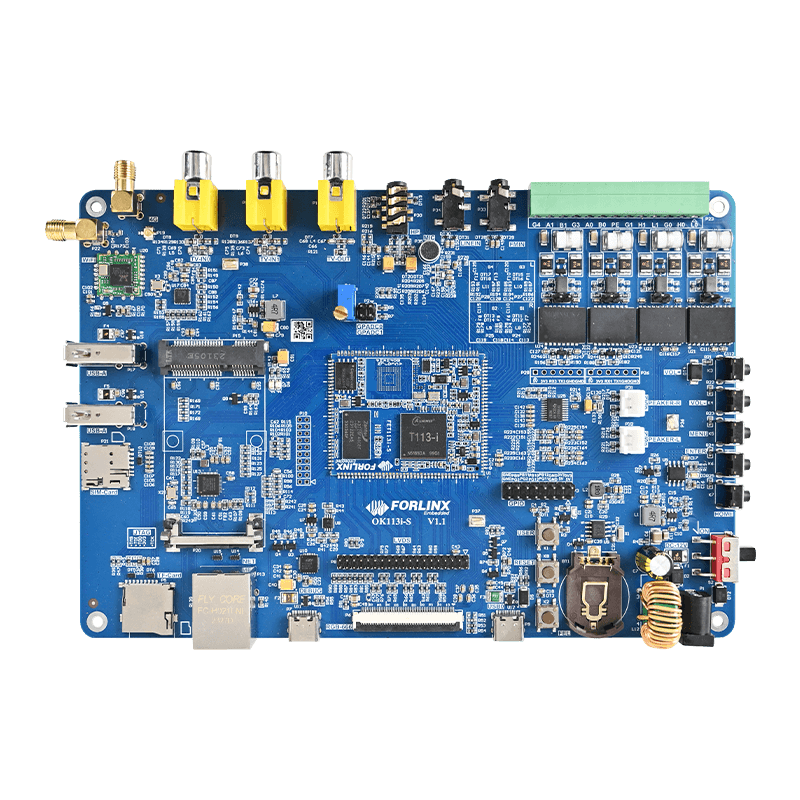

Recommended Hardware Platform: Forlinx T113 SoM

The T113 SoM stands out as a highly competitive solution for addressing the hardware challenges of peritoneal dialysis machines. Here are five reasons for its recommendation:

- High-Performance Computing: Integrates dual-core Cortex-A7 CPU, 64-bit XuanTie C906 RISC-V DSP with clock speeds up to 1.2GHz, providing robust computing power for precise control and real-time monitoring.

- Extensive Connectivity: Offers diverse connectivity options (USB, SDIO, UART, SPI, CAN, Ethernet) for flexible data exchange and communication, enhancing compatibility and future upgrade potential.

- Multimedia Support: Capable of decoding and encoding multiple formats with various display and audio interfaces, improving the user interface and feedback experience.

- Stable and Reliable Performance: Undergoes rigorous testing for environmental stress and long-term stability, ensuring consistent operation and high patient satisfaction.

- Cost-effective: Features compact, low-power consumption design ideal for portable devices, with competitive pricing to reduce overall machine costs and ease patient financial burdens.

In conclusion, the T113 SoM's combination of high performance, rich connectivity, multimedia support, compact size, and reliable operation makes it an excellent core hardware solution for peritoneal dialysis machines. It effectively addresses the need for control, monitoring, and user experience while reducing costs and enhancing market competitiveness.