Quadcopter of FET1052-C

Introduction:

The multi-rotor drone is an unmanned helicopter capable of vertical take-off and landing. Its development history can be traced back to 1907 when the Breguet brothers Louis and Jacque designed and manufactured the world's first manned helicopter under the guidance of French scientist Charles Richet. The multi-rotor aircraft being piloted-"Rotor One".

Multi-rotor UAVs can be divided into four-rotor, six-rotor, eight-rotor, and other types. There are also some special-shaped multi-rotor UAVs. The biggest feature is that they have multiple pairs of rotors, and the rotation of each pair of rotors is opposite. To offset each other's anti-torque moments.

Advantages of multi-rotor drones:

- Compared with fixed-wing aircraft, it has the advantages of vertical take-off and landing and fixed-point hovering;

- Compared with a single-rotor helicopter, it uses a brushless motor as the power and has no tail rotor device, so it has the advantages of simple structure, high safety, and low cost of use.

The many advantages of multi-rotor UAVs make them widely used in the following fields:

- Application in Educational Research: The research of multi-rotor drones involves automatic control technology, MEMS sensor technology, computer technology, navigation technology, etc., and is an ideal platform for fusion research in multiple scientific fields;

- Aerial photography application: The use of multi-rotor drones equipped with camera equipment (visible light camera/infrared camera), and equipped with an image transmission system, is widely used in film and television aerial photography;

In addition to the above scenarios, multi-rotor UAVs can also be applied to the police field, agriculture field, transportation field, environmental protection field, life-saving medical field, power industry, forestry fire protection, and other fields.

I. FET1052-C core board overview

The current more mature solution is an MCU for flight control, which needs to read sensor data, control flight attitude, and complete communication tasks. In addition, four dedicated MCUs are needed to drive the BLDC. Generally speaking, four dedicated MCUs will handle some other things in addition to controlling the motor and leave a margin.

These controls and operations can now be done with only one i.MX RT. The i.MX RT1052 is the industry’s first cross-border processor. It combines the high performance and high integration of application processors with the ease of use of microcontrollers. Combination of sex and real-time functions. i. MX RT1052 is an Arm® Cortex®-M7 architecture with a main frequency of up to 600MHz. It also has 4 sets of PWM modules, an ADC_ETC module suitable for multi-motor analog signal sampling, and a rich and flexible communication interface, so you can get the flight control + 4 BLDC Motor control is of course not a problem.

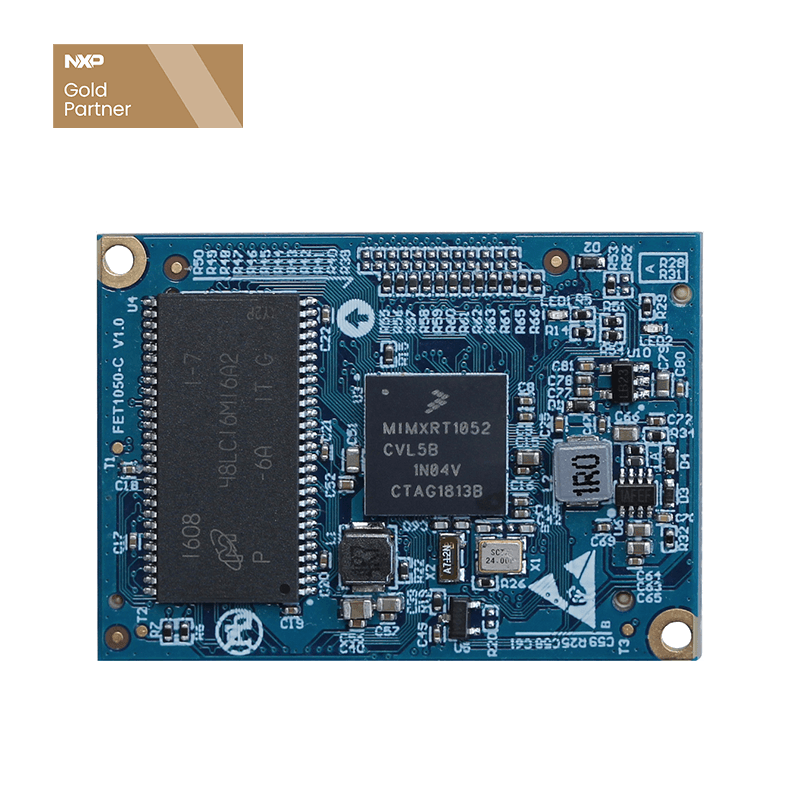

The FET1052-C core board of Forlinx has integrated the power supply, reset monitoring circuit, and storage circuit into a compact module. The external circuit is very simple. It only needs a 5V power supply, reset button, and start configuration to form a minimal system.

The core board leads out all the processor function pins, and 124 GPIOs can be configured. Supports LCD, Camera, USB, UART, CAN, Ethernet, PWM and other functional interfaces.

RAM and Flash can be configured flexibly, and the following two configurations are currently supported:

2. Hardware structure

The hardware structure of the FET1052-C core board

The drive board is equipped with a full carbon fiber frame with a 250 wheelbase and a 2212 motor. Strong power, equipped with 5.8G image transmission module, which can be used for aerial photography or flying through.

3. Circuit structure

Lithium battery charging circuit

Using the HY2213_BB3A chip, the balanced charging of the three lithium batteries is achieved by individually controlling the charging voltage of a single lithium battery, and the voltage of each lithium battery is collected by ADC and sent to the CPU to monitor the battery power in real-time and prevent the battery from being overpowered. put. When the battery is low, it will alarm and remind you that you need to return home, or automatically.

System power supply circuit

The FET1052-C core board only needs a 5V power supply, but the power-on sequence needs to be controlled, and the backplane power supply needs to be controlled by K7_ON_REQ. To ensure that the core board is powered on first and then the backplane, to prevent the occurrence of latch-up effects.

BOOT configuration

Select the startup mode through the dial switch.

Motor drive circuit

Three-phase bridge MOS tube drive circuit: FET1052-C core board outputs PWM to the gate driver unit (GDU: Gate Driver Unit). GDU is divided into a high-side gate drive and a low-side gate drive (HS/LS Gate Driver). Provide gate drive voltages for the high-side and low-side MOS transistors respectively, and the high-side driver also contains a bootstrap capacitor boost circuit;

Sampling resistor: A sampling resistor is connected in series with each phase drive circuit to convert the change of current flowing through the motor into a change of voltage;

Operational amplifier circuit: Amplify the voltage change on the sampling resistor and collect it to the ADC module of the MCU. The software restores the current change, thereby realizing the real-time detection of the motor phase current.

Sensor circuit

The sensor uses the gyroscope, acceleration sensor, and barometer with an IIC interface.

Wireless module circuit

The wireless module selects the 2.4G wireless transmitting module with an SPI interface. Through the signal enhancement circuit, the transmission distance is relatively long and the signal is relatively stable.

Image transmission module circuit

The image transmission module selects the 5.8G wireless transmission module. The image transmission is smooth and stable.

4.PCB design

A. Layout

When the motor rotates, a larger current is required, and the control and communication signal of the MCU is a small current signal. The commutation of the motor will cause the potential of the GND plane to change. The potential change of GND may affect the quality of the signal, and severely cause the abnormal reset of the MCU. Therefore, it is necessary to divide the high-current circuit and the low-current circuit.

The following figure shows a schematic diagram of the PCB layout of the four-channel ESC. Place the motor drive circuit on the right and the small-signal circuit on the left. The 2.4G and 5.8G wireless module circuits use a single PCB, which is connected to the mainboard through a flat cable.

B. GND division

With the above-mentioned PCB layout, the ground plane is well divided. The following figure shows the return paths of high current and low current respectively, and the two do not interfere with each other on the PCB. The power supply is divided into 12V and 3.3V power domains, GND is divided into large current ground and small-signal ground, and the two networks are connected at the power input end at a single point.

C. Signal routing

The trace from the sampling resistor to the op-amp circuit should be as short as possible, and a separate trace is pulled from the GND end of the sampling resistor to connect to the input terminal of the op-amp;

The impedance of the RF signal line is controlled at 50 ohms.

5. Conclusion

This is the end of the introduction to the four-axis aircraft solution based on Forlinx’s FET1052-C. It mainly shares the performance parameters of FET1052-C and the hardware design-related content of the four-axis aircraft solution, including the basic schematic circuit design and PCB. Layout considerations.

The Forlinx FET1052-C core board has powerful functions, rich interface resources, and simple secondary development. It is very suitable for applications such as drones, motion control and robots, indoor air conditioning systems, home appliance system control, and other fields. Pls, pay more attention.