Intelligent Inspection Robot Solution Based on FETMX8MP-C System on Module

01 Background

In the process of rapid urban development, more and more pipelines are laid underground. How can such a large underground utility network be efficiently and accurately maintained? Given the complexity and potential hazards of underground utility networks, underground inspection robots have emerged as a practical solution.

Indeed, it is possible to retrofit existing infrastructure with intelligent robot inspection and monitoring systems as well as disposal systems. By constructing a smart maintenance software platform, normal checks can be conducted on the fundamental attributes within the underground space to ensure the proper function of the facilities.

The pipeline robot can be divided into three main components: robot operation, IoT sensing, and application.

The robot operation part includes five main systems: cable subsystem, locomotion subsystem, power subsystem, communication subsystem, and positioning subsystem. These five subsystems are the basic guarantees that support the normal operation of the robot.

The IoT sensing part includes various sensing methods such as image capture, sound capture, temperature and humidity capture, hazardous gas capture, and infrared thermal imaging. These sensing methods are important ways for the robot to perceive the underground space.

The application part mainly involves processing the data collected by the IoT sensing part, including functions such as automatic warning subsystem, data analysis subsystem, remote management subsystem, etc.

02 Product features

1. Real-time detection and environmental monitoring: The robotic system is capable of monitoring the on-site environment in real-time, collecting information such as humidity, temperature, and harmful gas concentrations from the devices. It automatically analyzes whether these values exceed the alarm threshold and uploads the data.

2. Fully automated inspection: The robot conducts inspections based on preset schedules or through remote control via the cloud. Inspections can be categorized into two forms: routine daily tasks and special inspections. Special inspections refer to conducting inspections at specific locations designated by the cloud.

3. Automatic charging and low battery automatic return: The robot is capable of autonomously assessing the battery level and when it is low, it will automatically return to the charging station for recharging.

4. Autonomous obstacle avoidance function: The robot is equipped with sensors and is capable of automatically detecting obstacles in the track or pipeline environment during the inspection process. It will stop immediately and upload an alarm message if an obstacle is detected.

5.Inspection monitoring report: The robot will collect and process the inspection information it gathers, generating an inspection monitoring report that reflects the on-site conditions.

03 Product plan

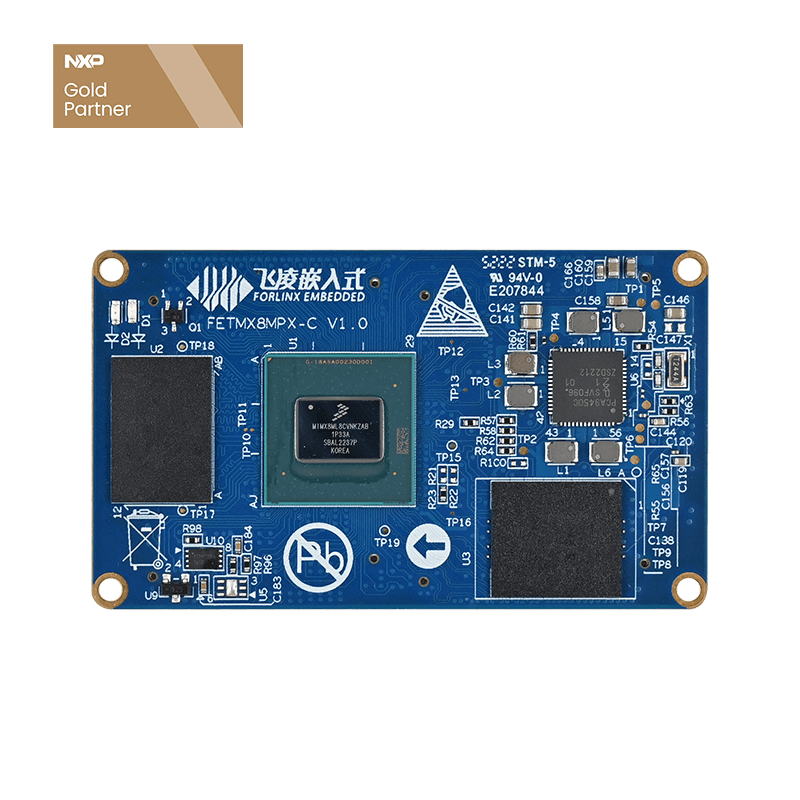

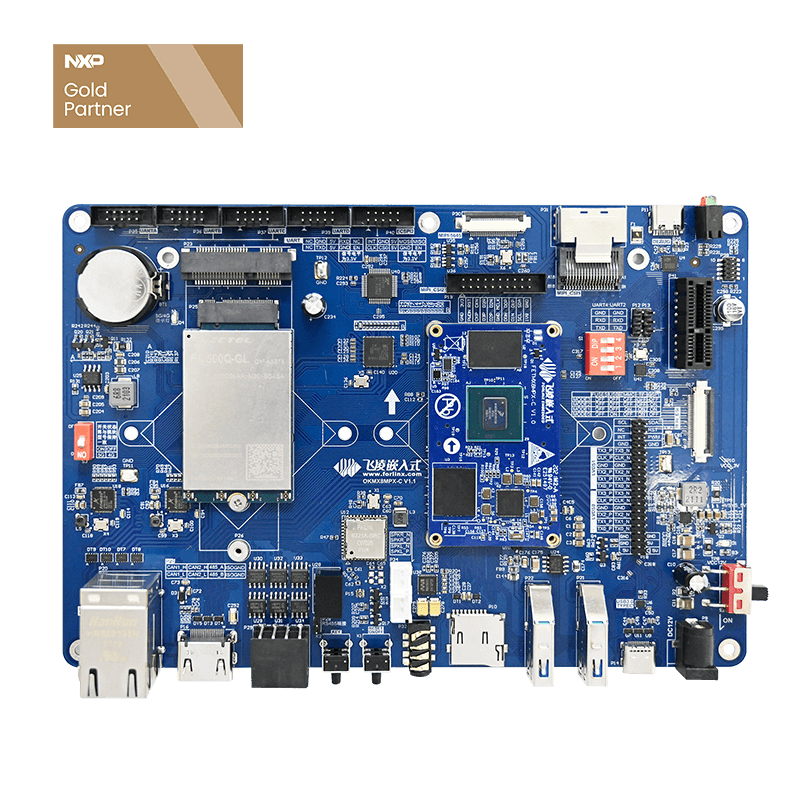

Based on the above features, we recommend the FETMX8MP-C System on Module as the core solution for the intelligent inspection robot for underground pipeline corridors to meet the customer's needs for machine vision and high-speed interfaces.

Forlinx Embedded has launched the FETMX8MP-C SoM, which is based on the NXP i.MX 8M Plus processor. It not only sets a new benchmark for machine learning and vision but also makes an ideal choice for pipeline robot applications. In applications such as pipeline inspection, maintenance, and monitoring, the FETMX8MP-C has outstanding performance and versatile features.

Smart Patrol: Equipped with a powerful Neural Processing Unit (NPU), the FETMX8MP-C enables intelligent analysis of pipeline conditions through machine learning, thereby improving inspection efficiency.

High definition images: With the advanced Image Signal Processor (ISP), the FETMX8MP-C produces high-definition images that assist pipeline robots in accurately identifying problems. Real-time video transmission: It supports video encoding and decoding, so that the pipeline robot can transmit video information inside the pipeline in real time.

Multi-communication interface: Rich communication interfaces, including USB3.0, PCIe3.0, SDIO3.0, CAN-FD, etc., enable the pipeline robot to flexibly respond to various connection needs.

Some market research institutes predict that the global pipeline Robot Market scale will exceed 2 billion US dollars by 2025. With the continuous development of global urbanization and the continuous expansion of oil and gas pipeline construction, the market growth trend of pipeline robots is undoubtedly worth looking forward to. Indeed, the development of smart cities, artificial intelligence, and 5G networks will bring even greater market opportunities for pipeline robots.