Based on Forlinx embedded AM5718 development board, logistics automated sorting delivery is realized

Feature overview and application areas

The domestic logistics industry started late, the level of development is low, in the application of information technology and developed countries have a big gap, developed countries have been widely used in some technical equipment in the domestic still rarely used, China's economic losses in logistics costs reached tens of billions of yuan per year, the realization of logistics information technology has become the inevitable trend of China's modern logistics development.

The implementation of the bar code identification system of express logistics improves the information level of logistics enterprises, and can greatly improve the efficiency of work, reduce costs and reduce errors.

The system uses industrial visual recognition technology to automatically scan the single barcode of the package surface after the logistics unloading.

The technology uses the image acquisition of the opposite single image of the intelligent camera, transmits the collected image to the image processing board for algorithmic processing, obtains the bar code data, then integrates the bar code data with the existing weight and volume on the bubble machine, and finally transmits the data to the data server through 2G/3G/4G technology, which facilitates the automatic sorting system in the later stage of sorting center.

The overall design and key modules

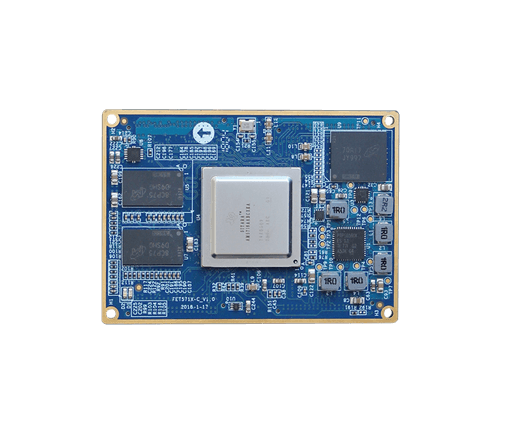

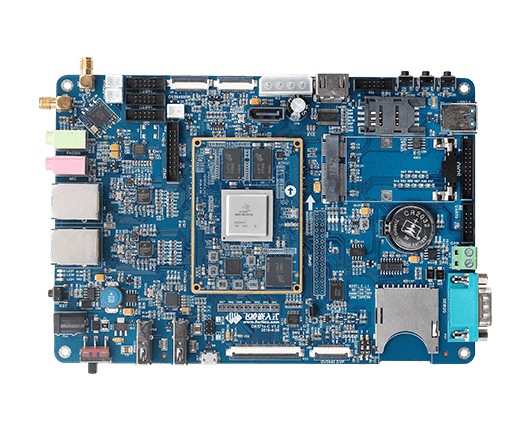

▼ Image acquisition and processing hardware system based on core board

The principle of visual detection of sorting systems

Visual inspection consists of two parts: detecting the color and shape of a package and identifying the barcode on the package list

1. Color and shape detection of the package

First, the package is identified by a color camera, and when the package reaches the camera directly below, triggering the camera to take a picture and capture the image, the processor ARM5718 will identify the captured image and process it by the algorithm.

The identification algorithm is as follows:

- a. Denoising the captured image;

- b. The image is divided according to the color characteristics, the area where the package is located is separated from the background, and the shape characteristics of the package can be calculated according to the edge characteristics of the split package area.

- c. In the area where the package is located in the image, the color features and rectangular shape features of the parcel sheet are analyzed by the connected area to identify the location of the parcel sheet. Determine the color characteristics of the package based on the area of the package in the image that remains after the package is removed.

2. Barcode identification

The package is photographed in a horizontal direction with four cameras at the same time. The number of camera shots is determined by the shape characteristics obtained in the previous step so that the vertical area of each package surface is captured by the camera.

The identification algorithm is as follows:

- a. Denoise the captured image

- b. Detect the presence of barcodes in the image you are working on

- c. For the image of the bar code area, the bar code area is precisely located and identified, and the results are output to the upper machine interface.

The main core technology of fixed image intelligent camera, with the following features:

Core board designed with TI (Texas Instruments) AM5718 multicore heterogeneous processor design

1, ARM Cortex-A15-C66xVLIW floating-point DSP heterogeneous hybrid processor

- a. ARM Cortex-A15 with a main frequency of up to 1.5GHz

- b. DSP C66x, main frequency 750MHz

- c. 2 dual-core ARM Cortex-M4, main frequency 213MHz

- d. 2 dual-core PRUs (programmable real-time units), main frequency 200MHz

- e. USB 3.0, PCIe3.0, HDMI1.4, UART, QSPI, CAN, Ethernet 1GB and other high-speed interfaces, with powerful video processing power and a wide range of applications.

- f. The operating system supports Linux4.9.41 plus QT5.6, TI-RTOS

2, Multi-core heterogeneous development platform

Provides a variety of command line and QT-side development routines, providing OpenCV, OpenCL, OpenGL development journey, DSP, PRU environment construction, and development process.

3, AM5718 Development Board With Powerful DSP

The development board integrates the C66X digital signal processor DSP with real-time computing, the main frequency 750MHZ, is widely used in audio processing, video processing, complex data algorithm processing and other fields, Anderlein provides OpenCV vision library integrated with OPENCV-DSP edge detection algorithm, face recognition, OPENCV-OPENCL-OPENGL and other reference DEMO, convenient for customers to develop quickly.

4, PRU programmable real-time unit

Equipped with 2 dual-core PRU-ICSS support for EtherCAT, EtherNET/IP, POWERLINK, PROFIBUS, PROFINET RT/IRT, SERCOS III, real-time fieldbus protocols and other industrial communications, the board provides developers with the low latency and real-time control required for industrial applications, and PRU real-time visibility can reach the ns level.

5, Rich multimedia functions

The development board integrates the SGX5443-D and GC320 2-D graphics accelerators for advanced graphical user interfaces, while the Cortex-M4 graphics processing unit IPU2 is designed for IVA image video hard-deconslating and supports H264, MPEG4 and many other encodings Format video hardware decoding playback, support multiple video simultaneous decoding playback, multiple simultaneous decoding total can reach 1080P 60 frames, support MJPEG image hardware codec, VPE support hardware image, video zoom, color space conversion.

6, Rich communication interface

The AM5718 development board with Dual Gigabit Ethernet communication interface to support Ethernet/IP and PROFINET protocols;

Support for RS232/RS485 bus and PLC, computer and other systems to connect;

Support for on-board WiFi-Bluetooth all-in-one modules and 4G communications.

Technical performance metrics achieved

In logistics applications, items from the tout to the dispatch center, from the dispatch center to the distribution process of many links need to scan the bar code on the document.

The code reader in this paper does not need manual operation, through the installation of fixed code reader on the automated assembly line, to achieve the automatic positioning and decoding of bar code. Based on fixed image intelligent camera, the efficiency and accuracy of the whole process have been greatly improved and guaranteed.