Comprehensive Testing Procedures for Embedded Boards: A Deep Dive into Forlinx Embedded's Million-Level Laboratory (Part 1)

The research and development laboratory serves as the technological backbone and innovation engine of any high-tech enterprise. Equipped with state-of-the-art facilities, standardized processes, and stringent standards, these laboratories ensure the advanced functionality, stable operation, and reliable quality of products amidst intense market competition.

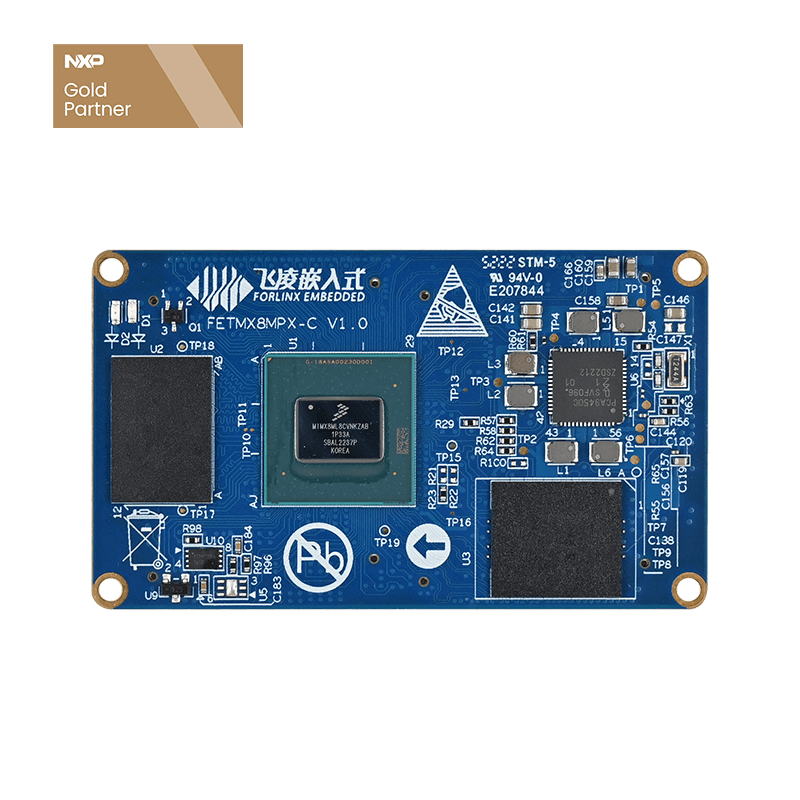

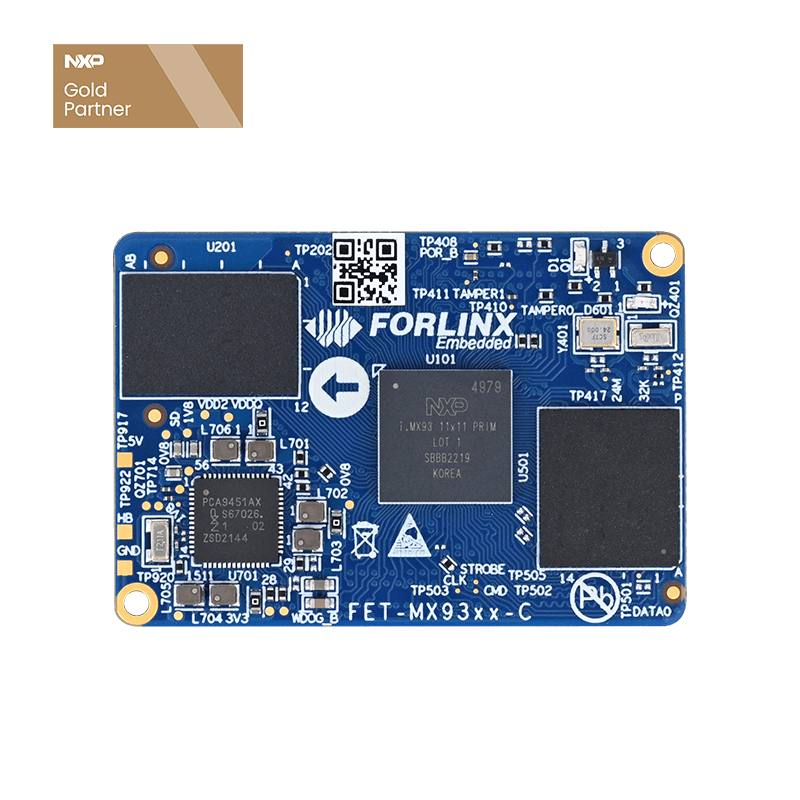

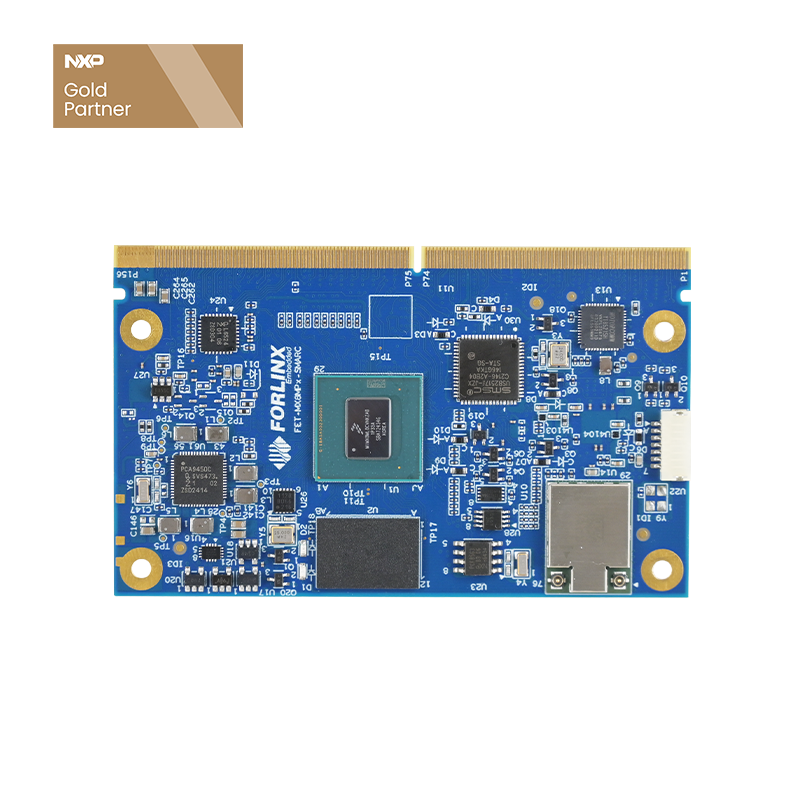

For over eighteen years, Forlinx Embedded has been instrumental in aiding thousands of enterprises to swiftly develop and launch their products. Additionally, it has consistently supplied stable batches of System on Module (SoM) and other products to numerous enterprises. These remarkable achievements are largely attributed to the robust support provided by its research and development laboratories.

To offer a more comprehensive understanding of Forlinx Embedded's exceptional R&D capabilities, we have produced a series of "Lab Visit" videos.

In this segment, we will introduce three critical tests: the Electrostatic Discharge (ESD) Immunity Test, the High-Low Temperature/Temperature Cycling/Humidity Test, and the Drop Test.

1. **Electrostatic Discharge Immunity Test**

Electrostatic discharge disturbances often occur during the operation of electronic devices, potentially causing circuit malfunctions and equipment damage. The ESD immunity test aims to evaluate the resilience of electrical and electronic equipment to electromagnetic disturbances.

2. **High and Low Temperature/Temperature Change/Humidity Test**

High and Low Temperature Tests, Temperature Change Tests, and Humidity-Heat Tests simulate extreme temperatures, rapid temperature changes, and constant humid conditions. These tests comprehensively assess the performance stability and adaptability of electronic and electrical products under extreme environments, preventing failures and ensuring reliable operation.

3. **Vibration Test/Shock/Impact Test**

Vibration tests simulate the vibration environments encountered during product transportation, installation, and use to assess product tolerance. Impact and collision tests simulate potential impacts to ensure products remain safe, reliable, and effective under external forces, covering various types of impacts.

Through these three videos, we believe you will gain a deeper understanding of the experimental projects at the Forlinx Embedded R&D Laboratory.

Our "Lab Visit" series videos are continuously being updated. We look forward to your continued attention and interest.