The ''Ice and Fire'' Trials of the Reliability of Embedded Products - High and Low Temperature Environmental Tests

High and Low Temperature Tests are methods for evaluating product performance by simulating extreme environments. In simpler terms, it involves putting products through an "ice and fire" test. It creates extreme temperature environments by placing samples in preset high-temperature, low-temperature, or temperature-cycling conditions to evaluate their adaptability, stability, and reliability.

For Forlinx Embedded, high and low temperature tests are a very important part of physical environmental tests. This is not intended to "deliberately torture" the products; rather, it aims to verify their performance in various temperature scenarios in advance. Following these tests, products will be better equipped to withstand harsh environments in real-world applications. The more comprehensive the tests, the more reliable the products will become.

Temperature Levels: Different Scenarios, Different Standards

Product usage scenarios vary widely, resulting in different requirements for high and low-temperature tolerance. In the industry, products can be broadly categorized into commercial-grade, extended commercial-grade, industrial-grade, and automotive-grade based on their temperature adaptation ranges. Each grade adheres to distinct high and low-temperature testing standards

| Grade | Temperature Range | Applicable Products | Scenario Examples |

| Commercial level | 0℃~70℃ | Home routers, TVs, etc. | Daily indoor environments, winter temperature, differences at home |

| Extended commercial - grade | -25℃~80℃ | Enterprise network equipment, new energy products, etc. | Consumer scenarios with higher temperature requirements |

| Industrial-grade | -40℃~85℃ | Industrial control equipment, electronic components of machine tools, etc. | Factory workshops, outdoor industrial sites |

| Automotive - grade | -55℃~125℃ | In - vehicle central control systems, engine control units, etc. | High temperatures in the engine compartment, low temperatures in northern winters |

Commercial-grade: This category primarily involves daily consumer electronics, such as home routers and TVs. The temperature range typically spans from -20°C to 0°C (low temperature) and around 70°C (high temperature). The test conditions are relatively lenient, simulating the temperature scenarios encountered in daily life.

Extended commercial-grade: Building on the commercial-grade standards, this category sets higher requirements for specific consumers or usage scenarios.The temperature range extends to -25°C to -10°C (low temperature) and 70°C to 80°C (high temperature).

Industrial - grade: Designed for control equipment used in industrial production and electronic components in machine tools, this grade further expands the temperature range to -40°C to -20°C (low temperature) and 70°C to 85°C (high temperature). Products in this category must adapt to complex environments, such as factory workshops and outdoor industrial sites, with exceptionally high demands for product stability.

Automotive-grade: Given the harsh conditions found in vehicle environments, this grade covers a temperature range of -55°C to -40°C (low temperature) and 85°C to 125°C (high temperature), with varying requirements for different parts. For instance, components inside the vehicle cabin generally need to withstand temperatures of 85°C, while those in the engine compartment must endure up to 125°C. The testing protocol involves simulating high- and low-temperature cycles to ensure that products can withstand extreme temperature fluctuations during vehicle operation.

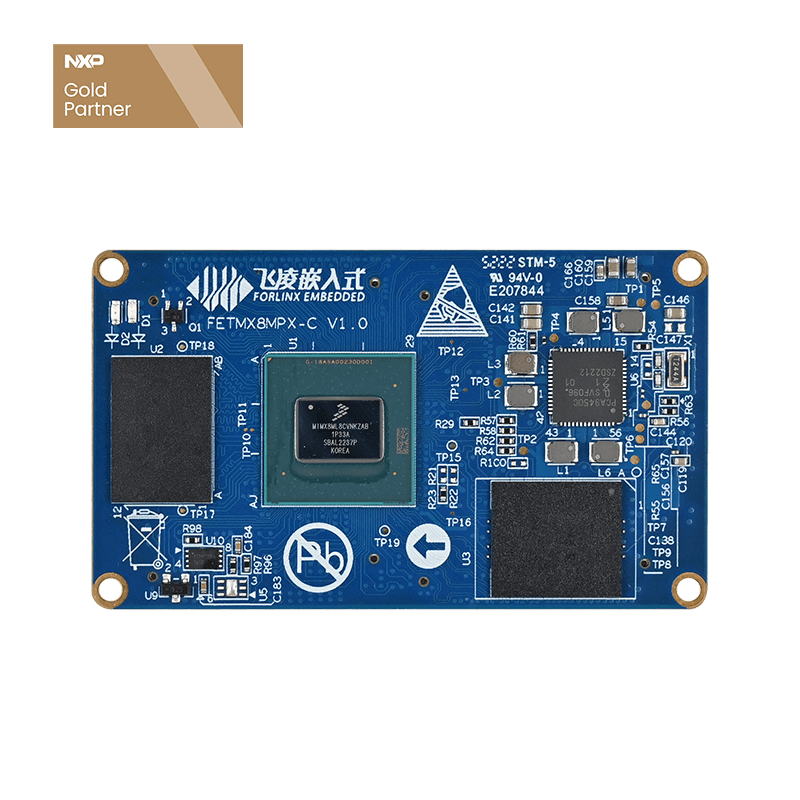

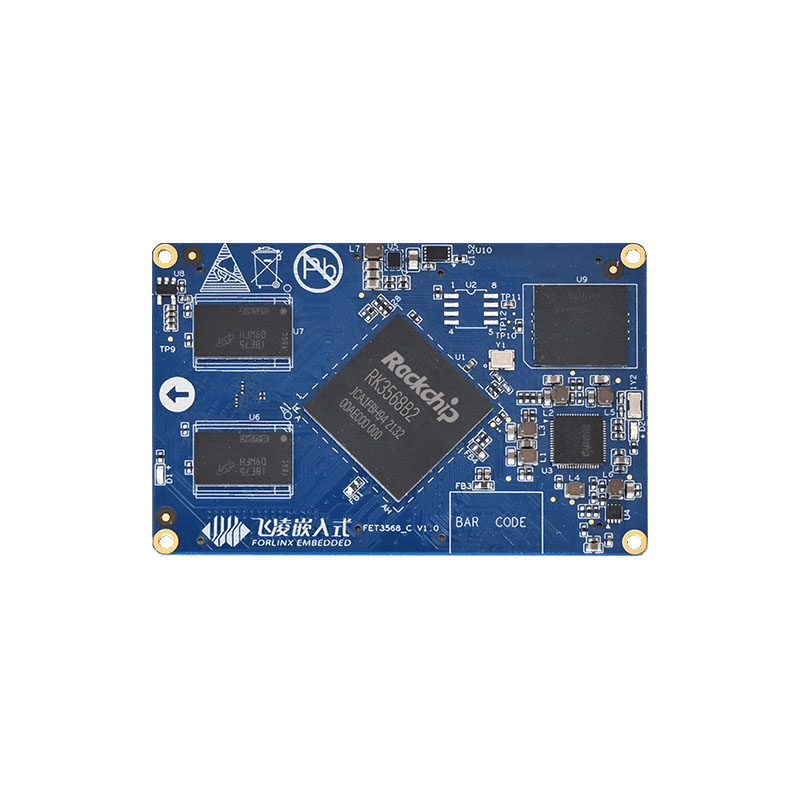

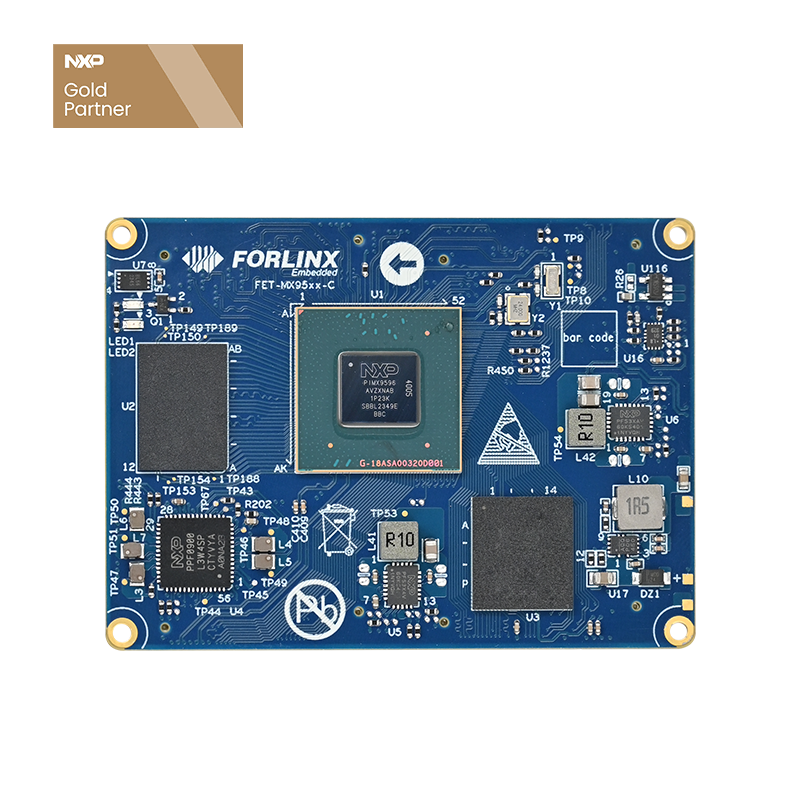

It's worth noting that the products offered by Forlinx Embedded primarily fall into three temperature adaptation categories: industrial-grade, commercial-grade, and extendedcommercial-grade.

Standardized Tests: Scientific and Rigorous, Based on Evidence

High and low-temperature tests are not conducted arbitrarily; rather, they must adhere to a series of strict standards. Different industries and products have clearly defined standard requirements, including GB/T 2423.1-2008, GB/T 2423.2-2008, IEC 60068-2-1:2025, IEC 60068-2-2:2025, GB/T 15153.2-2000, and IEC 60870-2-2, among others The test conditions—such as temperature range, duration, and heating and cooling rates—must be strictly followed according to these standards.

These guidelines ensure the scientific rigor of the high and low-temperature tests.

Test Process: Precise Operations, Step by Step

High and low-temperature tests are carried out in a specialized ''high and low-temperature test chamber.'' The process is divided into three stages: preparation, testing, and completion, with each stage requiring precise operations to avoid errors.

1. Preparation Stage:

It is essential to verify that the sample corresponds to the model being tested. Additionally, ensure that all tools and connection cables are securely attached, paying close attention to cable lengths. The sample should be tested with the startup program to confirm that the feedback results meet the specified requirements. If conducting a cyclic test, at least two rounds of testing should be performed to verify the method's effectiveness.

A testing engineer conducting high and low temperature tests

2. Test Stage:

First, place the samples into the test chamber, allowing for a 10-cm gap between samples and between the samples and the chamber walls to ensure proper ventilation.

The specific experimental process proceeds as follows:

Power on the sample, run the test program, and start data logging;

Close the chamber door, set the low temperature (confirm the setting), and begin timing for 24 hours after reaching the target temperature, inspecting every 4 hours;

After turning off the sample power for 30 minutes, power it on five times at 10-minute intervals and start it ten times at 1-minute intervals without turning it off, recording the results;

Power the sample back on and run the test program;

Set the high temperature (verify the setting), time for 24 hours after reaching the target temperature, and conduct inspections every 4 hours;

After turning off the sample power for 30 minutes, power it on five times at 10-minute intervals and start it ten times at 1-minute intervals without turning it off, recording the results;

Back up the records, allow the chamber to cool to room temperature, and remove the samples after 10 minutes.

3. End Stage:

Following the test, a final inspection of the samples is necessary, including evaluations of appearance, function, and performance parameters, to determine if they meet product specifications.

Finally, compile the data into a report: organize the temperature data, detection results, and sample statuses during the test into a ''High and Low-Temperature Test Report.''

Conclusion: Guarding Product Reliability with Stringent Tests

Although high and low-temperature tests may seem like they are "making things difficult" for products, they actually serve as the "guardians" of product reliability. By using extreme environments to simulate real-world challenges according to different grade requirements, these tests help identify potential issues in advance, ensuring that products can operate stably across various temperature scenarios.

For Forlinx Embedded, clearly defining the temperature grade of products and conducting corresponding high and low-temperature tests is not only a commitment to product quality but also a responsibility to users in future developments, Forlinx will maintain a rigorous and scientific approach to provide comprehensive quality assurance for each product.