Why Use Embedded Core Board Develop Products?

What is Embedded Core Board?

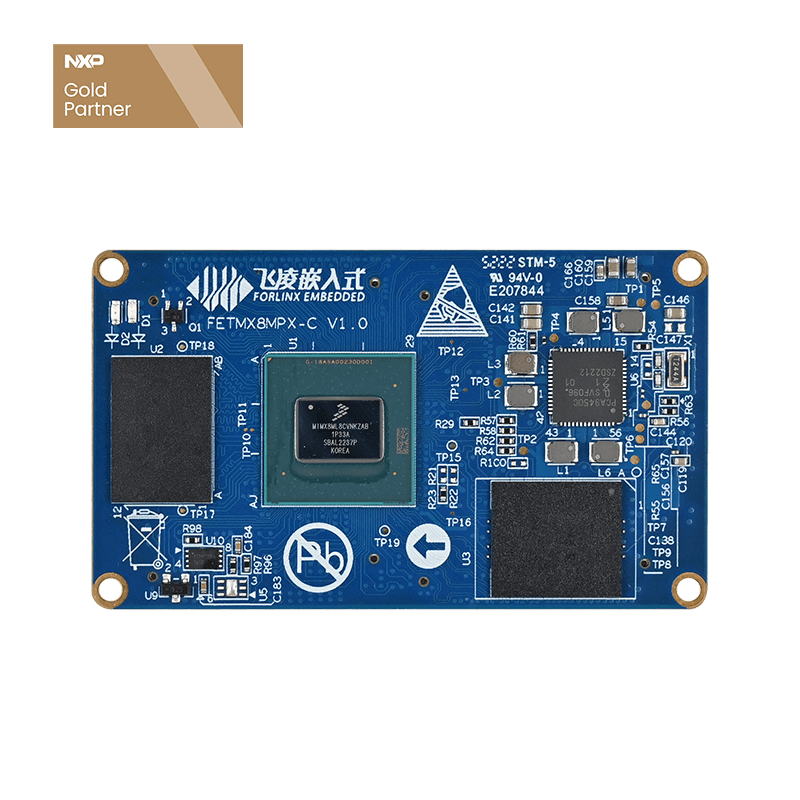

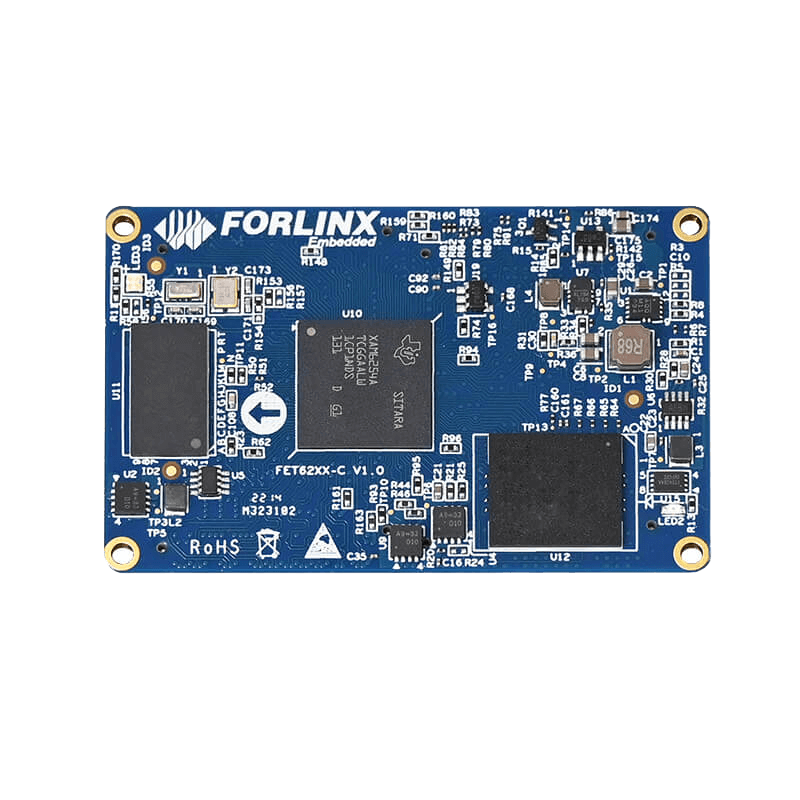

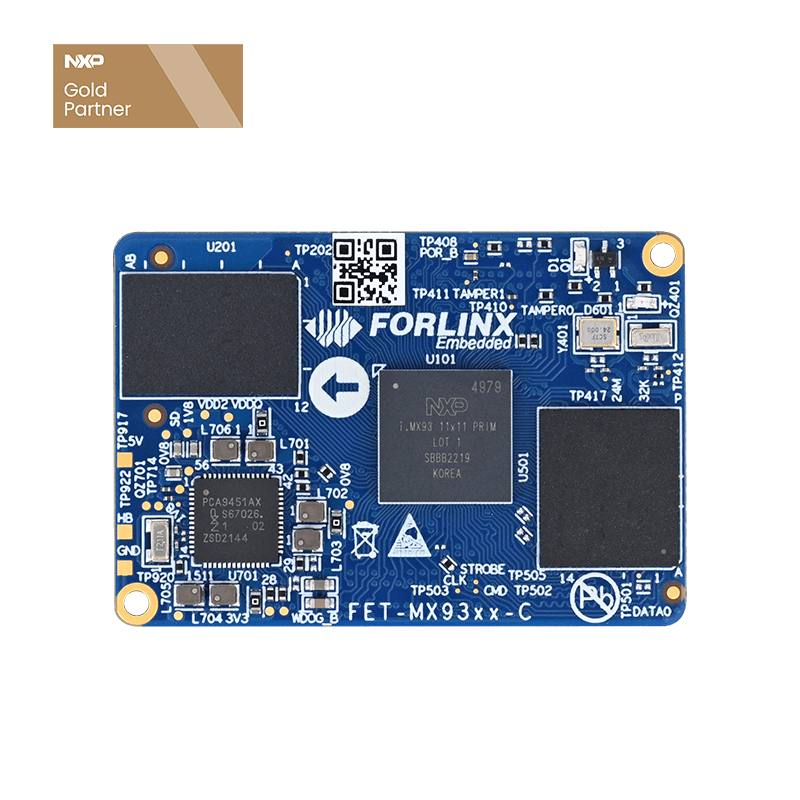

The embedded core board, also known as the System on Module (SoM) board, is a highly integrated board that encapsulates integrated chips such as CPU, memory (DDR), storage (eMMC or FLASH), power management (PMIC, responsible for the timing of CPU and output of different voltages in CPU demand), and generally uses board-to-board connectors, stamp hole welding, gold fingers, COM Express, etc. And the core board usually leads out all or most of the functional pins of the CPU, the user only needs to design the peripheral circuit of the functional interface when designing the product, thus reducing the difficulty of hardware development and saving development time.

In terms of software, the embedded core board (hereinafter referred to as the core board) has generally completed the porting of Linux (Build Root), Ubuntu, Android, WinCE and other embedded operating systems, in the improvement of various interface drivers at the same time will also adapt to Uboot, file system graphical interface porting development, so that the final presentation to the user is a full operating system with graphical interface, to maximize the convenience of the user for secondary development.

As a unique form of embedded board, the core board has obvious advantages over the all-in-one board, which can not only reduce the difficulty of product design and speed up the time to market, but also facilitate product iteration upgrade and reduce maintenance workload, so it is widely used in the product field involved in embedded systems. For some experienced software and hardware engineers, may not understand the development of the core board or do not trust the core board product model, so whenever there is a new project development to start designing the all-in-one board, software also have to re-port Uboot, operating system and so on. This approach is feasible if time is sufficient and experienced, but many companies have a relatively weak foundation on hardware and underlying drives, and if the design process fails, it is likely that the entire project will be shelved, affecting the product launch. In the case of insufficient manpower, such work is undoubtedly in the "repeated wheel", invisibly consuming a lot of human and material resources.

In fact, Forlinx embedded core board after many years of technical development and quality precipitation, in the integration, stability, professionalism and other aspects have been very mature, Forlinx's enterprise-class board for users to carry out product development can bring a lot of value. Next, let's take a closer look at product development.

Embedded ARM Terminal Product Development Difficulties

Embedded processor applications are already widespread, but there are some inesoventive pain points in hardware design, software development, and production maintenance when developing end products.

01. Hardware Design Points

Design difficulty: With the development of embedded technology, embedded processor performance is getting higher and higher, compared with the development is more and more difficult, is not a microcontroller engineer hard and soft to eat the era. From SDRAM to LPDDR4, memory rate is getting faster and faster, PCB layer number can be satisfied from the early 4 layers to the present 8-12 layers, high-speed trace and hardware simulation have a great demand, high hidden cost of development investment.

Design cycle is long: from familiar with CPU start-up, memory selection to power architecture design, moving hundreds of wires, generally need more than half a year to complete hardware design and testing;

Stability testing is complex: high and low temperature test, pressure test, signal integrity test, power belt test, long-term running stability test, frequent power failure, power switcher testing, etc. need to have complete test equipment and experience to complete. Failed testing at any one point could re-engineer the design and increase the pressure on engineers.

The above questions, if using the Forlinx core board?

The use of Forlinx core board design products, because high-speed signal traces are all concentrated in the core board level, users only need to carry out peripheral functional interface circuit design, so that the number of PCB layers from 8-12 layers to 2-4 layers, greatly simplify the hardware design difficulty, reduce the development cycle. At the same time, a variety of complex tests for core modules have been completed by Forlinx, and testing costs will be significantly reduced.

02. The Point of Software Design

Long system porting cycle: Adapting to an operating system that meets the needs of the product requires a long development cycle. File system tailoring, document interpretation, adaptation of hardware, BUG debugging, all kinds of work undoubtedly increased the difficulty of development, but also extended the development cycle;

Repeat development: When an enterprise has different product development projects, it selects different brands or models of embedded processors based on the characteristics of the product, which vary in performance and price. Overperform or underperformance can occur if you develop different products with the same processor, but if you choose a different model of processor development for each project, there will be duplication of development and insufficient effort. Importantly, the end-product enterprise's software research and development energy is more suitable for application development, hardware-related kernel layer needs to change with the processor changes;

The above questions, if using the Forlinx core board?

The operating system BSP package of The Forlinx core board is optimized, repaired, cropped, and tested and exported, and the usage habits, functional features and stability are more in line with user needs. Users no longer need to make a few hundred gigabytes of data from the original chip to meet their functional needs BSP step by step, only from The established development environment provided by Forlinx in accordance with the software manual operation, not only save the development cycle, but also let the user's energy more focused on the development of applications.

03. Production and Maintenance of Points:

Production yield control difficult: embedded processor development of product PCB layer, and most of the high-speed signal, PCB material, material quality, welding quality requirements are very high, if the consistency of production will directly lead to the decline of good yield and even cause board instability in the field.

Long product maintenance cycle: high-speed signal on the PCB impedance requirements, material changes are likely to lead to memory parameters adjustment. In addition, some industries have a long product life cycle, moving more than ten years, the process of any chip production or update needs hardware and software-driven modifications, although not difficult but always have to be maintained, distracted.

The above questions, if using the Forlinx core board?

Because the processor, memory, storage and power management and other major chips are integrated in the core board, and All of Forlinx core boards before the factory will undergo rigorous aging and testing, to ensure delivery to the user is qualified products, so from the side to improve the user's product stability, reduce its production difficulty. Because the processor, memory, storage and other chip production processes are constantly updated iteration, software updates are inevitable, Forlinx in order to ensure the consistency of the core board, will continue to maintain the core board upgrades, which indirectly help users reduce maintenance costs and effort.

Conclusion

Medical, industrial control, transportation, power, Internet of Things Different industries, different products on the embedded processor demand is different, some demand high performance, some demand low cost, some demand a wealth of functional interfaces. In the embedded processor market, Forlinx reached a strategic partnership with NXP, Allwinner, Rockchip, TI, SAMSUNG, Renesas and other domestic and foreign chip originals, for the characteristics of different embedded processors launched a series of core boards, both dedicated network acceleration NXP DN product processor core board, but also multimedia universal processor core board; Eliminate the need for different industry users to develop multiple boards due to different project needs.

And stable and reliable embedded core board, in the product development stage, bring not only the reduction of research and development difficulty, research and development cycle shortened, in the long run can also save the hidden cost of product batch. This is why more and more enterprises choose to use core boards to develop products, because for engineers and business owners, they are effort-saving, but also to make the product more stable.