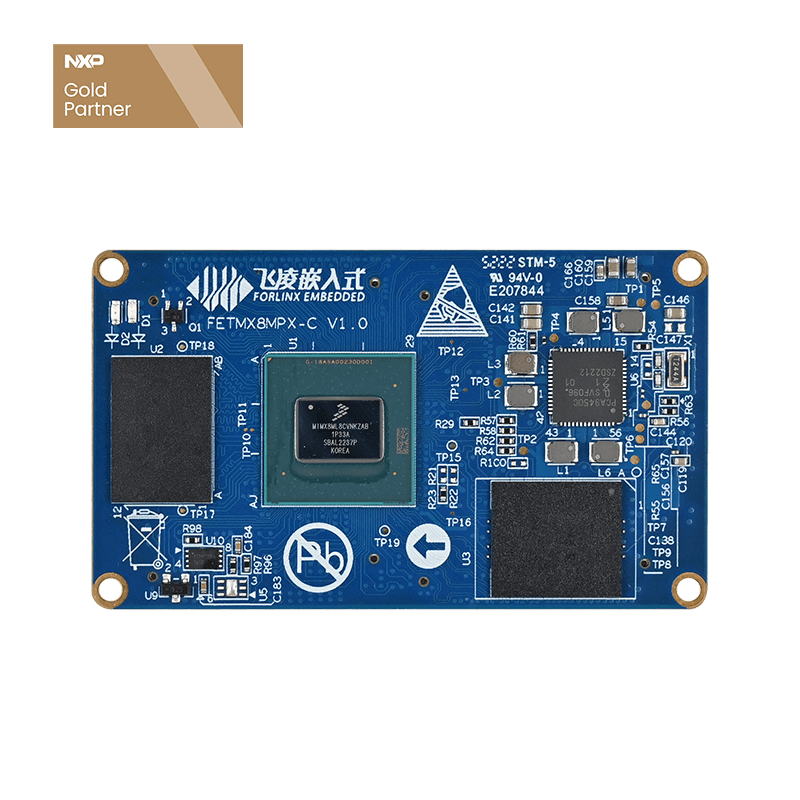

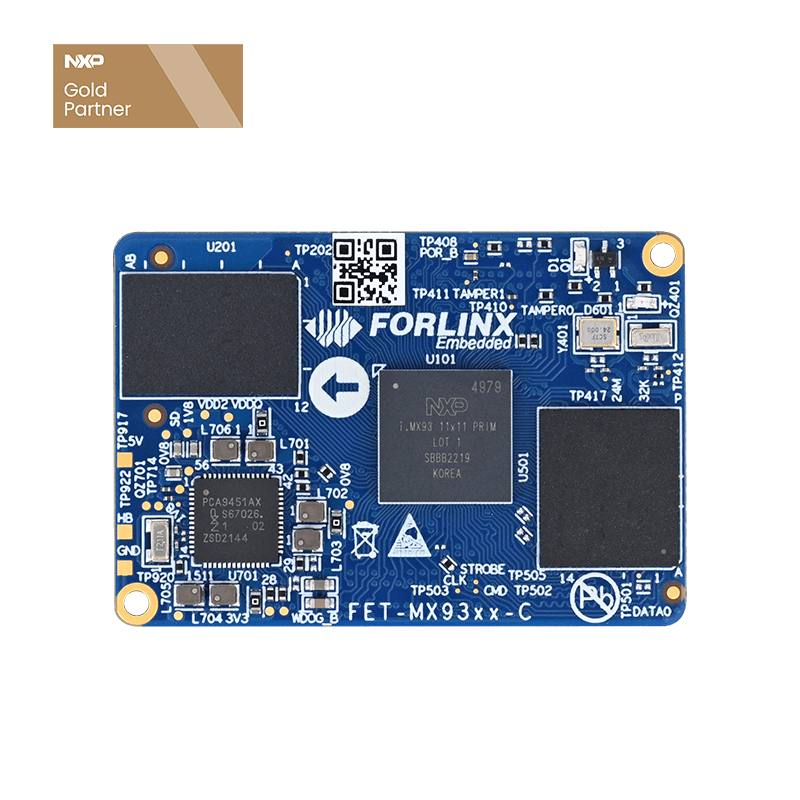

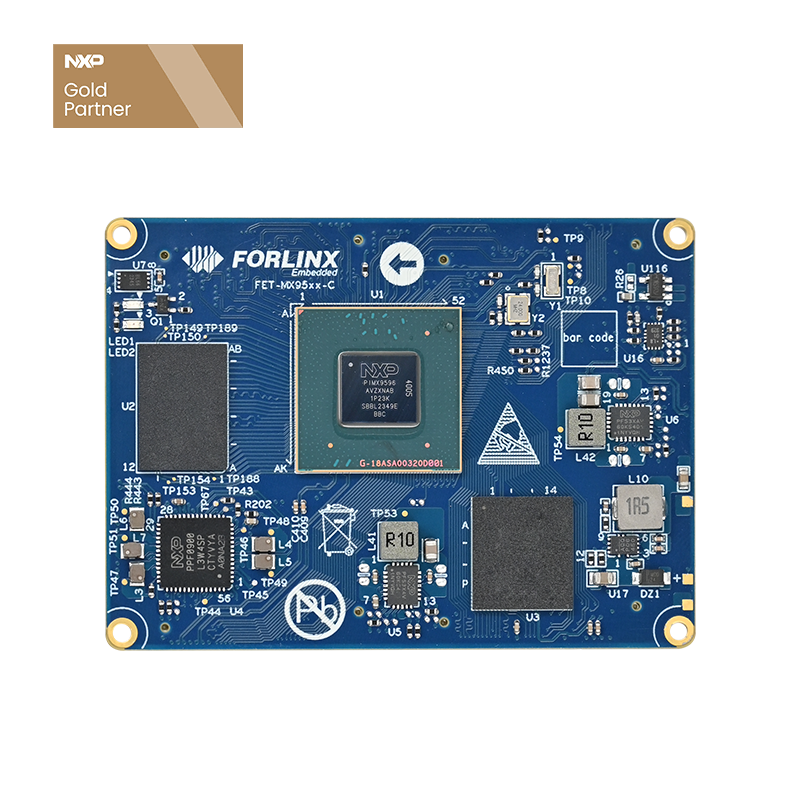

Forlinx Embedded's SoMs Pass 24 Hour Aging Test for Reliable Delivery

In Forlinx Embedded's production and testing process, there's a must - do step: every SoM has to complete a continuous 24 - hour aging test before it can be shipped out of the factory. Behind this simple - sounding time requirement is Forlinx Embedded's unwavering dedication to product quality. The goal is to deliver products that customers can rely on without a second thought.

1. Why Subject SoMs to Tough Tests?

The aging test, as the name suggests, involves running the product continuously in a simulated real - world working environment to quickly uncover potential defects. It's like giving each core board a thorough ''physical examination'' to catch those hard - to - find quality problems before they reach the market.

The main purpose of the aging test is to filter out early - stage failures. Electronic components follow the so - called ''bathtub curve'' failure pattern. In the early life of a product, because of potential flaws in materials and manufacturing processes, the failure rate is relatively high. By conducting the aging test, Forlinx Embedded can identify these ''problematic boards'' and prevent them from getting into customers' hands.

Verifying performance stability is also super important. During the 24 - hour continuous operation, Forlinx Embedded puts the CPU, GPU, NPU, memory, eMMC, etc. under stress. The test data not only validates the product's current performance but also guarantees its long - term stable operation.

Ensuring quality consistency is a key aspect in mass production. Even if the same design and materials are used, there may still be slight differences between different production batches. The burn - in test makes sure that every SoM delivered to customers meets the same high - quality standards.

2. 24 Hours: A Well - Thought - Out Test Duration

Why 24 hours? This time limit is based on a large amount of practical data and reliability engineering principles.

In the ''bathtub curve'' of product quality, early failures mostly happen in the initial working stage. Through statistical analysis, it is found that a 24 - hour continuous test can effectively cover the period when most early failures occur. This duration strikes a good balance between test effectiveness and delivery speed.

During the test, each SoM runs the test program non - stop. Running at full capacity tests its processing power and reveals potential issue

3. Challenges in Scaling Up: More Than Just Time

For Forlinx Embedded, conducting aging tests on all SoM products for delivery means facing several challenges.

Time is the most obvious challenge. Each SoM needs 24 hours of testing, which definitely slows down the production cycle. To balance efficiency and quality, Forlinx Embedded has built a large - scale professional aging test workshop. Through smart scheduling and parallel testing, the company has optimized the whole process.

Equipment investment is another big deal. Professional aging test equipment and data acquisition systems cost a lot of money. Also, facilities like environmental control and power supply at the test site are equally essential.

Technical expertise is the core challenge. How to design effective test cases? How to set appropriate environmental parameters? How to accurately interpret the test results? All these require in - depth technical knowledge and extensive practical experience.

4. Value Return: Invisible Quality Assurance

Despite facing numerous challenges, Forlinx Embedded always believes that the investment in the 24 - hour burn - in test is worthwhile and necessary.

For customers, it means higher reliability. The early failure rate of the SoMs that have undergone the aging test can be reduced by more than an order of magnitude, greatly enhancing the system stability. For the production process, the aging test provides valuable data feedback. By analyzing the test data, it can continuously improve the design and manufacturing processes, forming a positive cycle of quality improvement.

In addition to the 24 - hour aging test, Forlinx Embedded also conducts a series of strict tests and inspections on its products, such as signal integrity tests, high - and - low - temperature tests, electromagnetic compatibility tests, and full - function tests. This rigorous attitude reflects Forlinx Embedded's sense of responsibility towards customers. Quality is not just an empty slogan but a practical action implemented in every production link.

The introduction of the test items in Forlinx Embedded's R & D laboratory has been compiled below by the editor. Friends who are interested can click to check .

- ▶ Visit Forlinx Embedded's R & D Laboratory (Episode 1)

- ▶ Visit Forlinx Embedded's R & D Laboratory (Episode 2)

- ▶ Visit Forlinx Embedded's R & D Laboratory (Episode 3)

5. Conclusion

The 24 - hour aging test of the SoMs is just a microcosm of Forlinx Embedded's many quality assurance measures. In an era that pursues rapid iteration, Forlinx Embedded is still willing to spend 24 hours continuously safeguarding quality. Because Forlinx deeply understand that reliability is the lifeline of embedded products and the cornerstone of customer trust.

Each SoM that has passed the aging test carries not only technical parameters but also Forlinx Embedded's commitment to excellent quality. This commitment stems from our respect for the industry, our promise to customers, and our profound understanding and strict requirements of our own responsibilities.

At Forlinx Embedded, quality assurance is always on the way. Because of your trust, Forlinx Embedded will continue to go all out!