Electrochemical Energy Storage | BMS Solution based on ARM SoM

1. Electrochemical Energy Storage

Electrochemical energy storage is a new energy storage method that stores electrical energy through flow batteries, lithium-ion batteries, and sodium-sulfur batteries. It is commonly used in minutes to hours working site.

The proportion of electrochemical energy storage in total energy storage market is increasing, and it is applied on the power generation side, grid side, and power consumption side.

Electrochemical energy storage industry chain

Electrochemical energy storage system is composed of a battery module, energy storage converter (PCS), battery management system (BMS), and energy management system (EMS). Among them, battery module is for power storage; PCS is a converter connected between battery system and grid (or load) to realize the bidirectional conversion of electric energy; BMS and EMS are management and control centers of the energy storage system.

BMS is for monitoring battery data and protecting battery safety; EMS is for energy control of internal microgrid of the energy storage system by data acquisition, network monitoring, and energy scheduling to ensure normal operation of microgrid and entire system.

Schematic diagram of electrochemical energy storage system

In this system, the cost of battery modules and PCS is relatively high. Although the hardware cost of BMS and EMS is not high, they are the management and control center of the whole system. Their performance and functions will directly affect operation efficiency and stability of whole system. And, it has certain difficulties to develop them. So they are still the focus of this industry.

With the continuous increase in installed capacity of electrochemical energy storage systems, the demand for BMS and EMS will change more and more due to differences in projects, battery capacities, and cooling methods. It becomes very important to reduce the difficulty of their development.

At present, EMS mostly adopts the form of PC and server, while BMS hardware mostly adopts the form of x86 industrial computer or embedded ARM motherboard. In terms of economy, embedded ARM motherboard has more advantages; from the perspective of BMS development, choosing a mature and stable embedded ARM core board as main control will make the entire product development process simple and efficient. It can also reduce some repetitive hardware design work caused by project changes.

Therefore, this article will introduce a feasible solution of BMS based on embedded ARM SoM, which can be a reference for selection by companies in this industry.

2. Battery Management System

BMS is composed of a battery array management unit (BAMS), battery cluster management unit (BCMS), and battery management unit (BMU).

2.1 Battery Array Management Unit (BAMS)

It's the "host computer" in BMS for collecting, analyzing, and controlling the data of the entire BMS system. It has complete event records and historical data storage, including battery system charge and discharge, and operating parameter settings.

2.2 Battery Cluster Management Unit (BCMS)

Responsible for monitoring and controlling battery management unit, including battery fault diagnosis, balance control strategy, and remaining power estimation.

2.3 Battery Management Unit (BMU)

It is for collecting and uploading voltage and temperature of the battery module and realizing two-way efficient and active balance of power between battery cells.

Topological diagram of electrochemical energy storage system

Taking a 1MW energy storage power station as an example, BMS needs one battery array management unit, 1~4 battery cluster management units mounted by CAN, and each battery cluster management unit can be mounted with 1~14 batteries management units by CAN, and then battery management unit performs data collection on battery module. Typically, each battery module consists of 4 parallel 16 strings of batteries.

For each unit module of BMS, Forlinx Embedded has embedded ARM SoM with high adaptability, which can be a reference for selection, helping users flexibly and quickly build a set of stable BMS according to project requirements.

3. Scheme realization

3.1 Battery array management unit

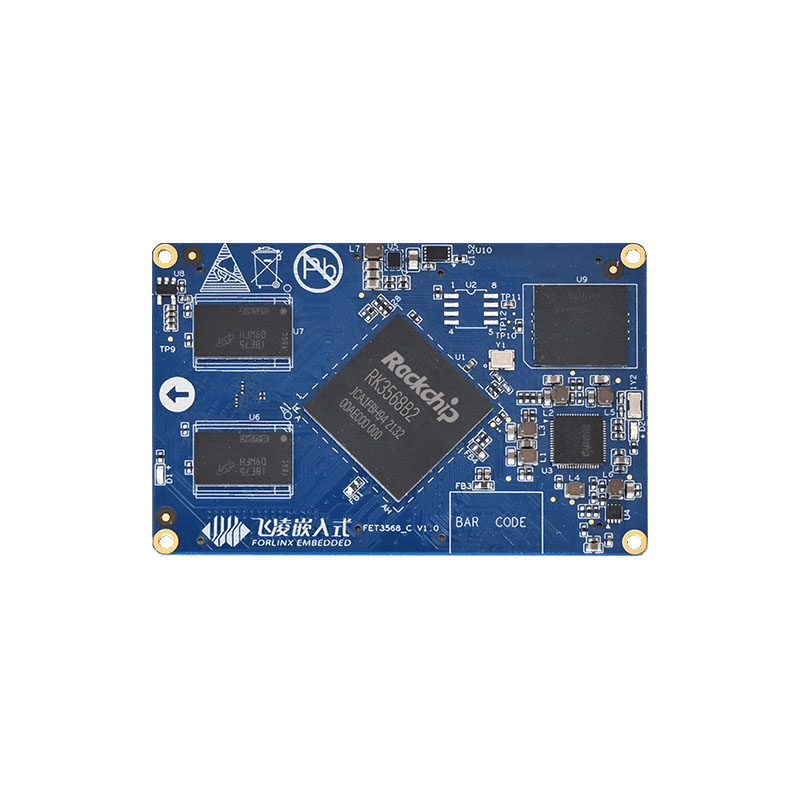

Recommended board: FET3568-C system on module(SoM) >>

FET3568-C SoM is designed and developed based on Rockchip RK3568, quad-core 64-bit Cortex-A55, up to 2.0GHz.

It has rich functional interfaces, supports multi-channel CAN and UART (communication with battery cluster management unit and other auxiliary equipment), 2-channel Gigabit Ethernet (easy for networking), RGB, LVDS, HDMI (for human-computer interaction interface), supports high-speed interfaces such as PCIe3.0 and STAT3.0 (connect the hard disk to expand local storage).

3.2 Battery cluster management unit

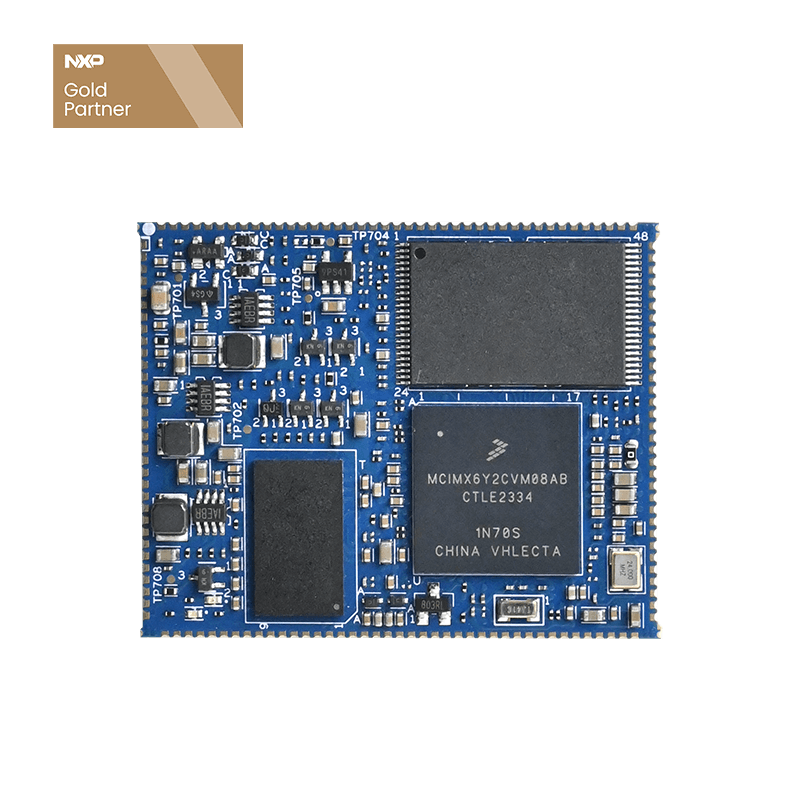

Recommended board: FETMX6ULL-S system on module(SoM) >>

FETMX6ULL-S SoM is designed and developed based on NXP MCIMX6Y2, Cortex-A7, 800MHz, excellent cost performance, and stable operation.

It supports 3 channels of CAN (native 2 channels, 1 channel SPI to CAN), 2 channels of Gigabit Ethernet, and 8 channels of UART, which can meet the performance and cost requirements of the battery cluster management unit. And it has rich development resources, easy to develop, and can quickly develop a series of similar products.

3.3 Battery management unit

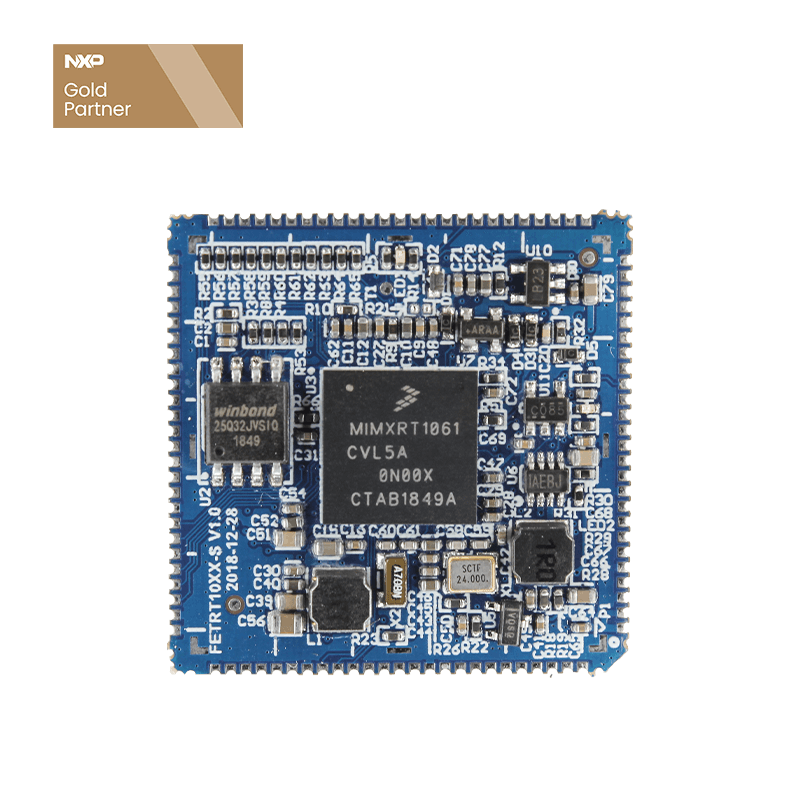

Recommended board: FET1061-S system on module(SoM) >>

Battery management unit is different from battery array management unit and battery cluster management unit. It can be realized by MCU, so FET1061-S SoM is recommended.

FET1061-S SoM is ARM Cortex-M7, which combines low power consumption and ease of use of microcontroller, and high performance and high scalability of the application processor. It supports multi-channel CAN, 2-channel Fast Ethernet, and up to 32 high-speed GPIO, which can easily collect multi-channel battery data.

Above are recommended BMS solution based on embedded ARM SoM. Forlinx Embedded has been in the power industry for 10+ years, has accumulated rich and mature product implementation experience, and can provide high-quality technical services for the energy storage industry. If you are selecting energy storage products, welcome to consult Forlinx sales engineers for details.