How to Build the Core of Visual Analysis in Smart Factories with the FCU3501 AI Edge Computing Box

As intelligent processes increasingly impact the industrial manufacturing sector, factory workshops are transitioning from an ''experience-based'' approach to a ''data-empowered'' model. The challenges of manual visual inspection in detecting defects on production lines, the gaps in monitoring personnel behavior, and the slow response times in tracking equipment status are significant obstacles. These issues continuously hinder improvements in both production efficiency and quality.

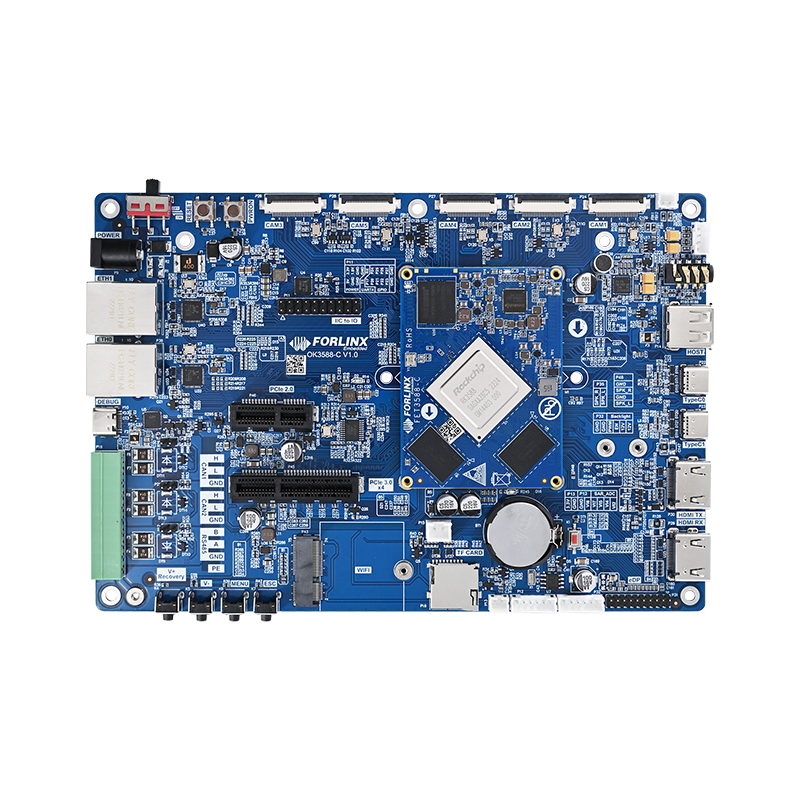

Forlinx Embedded FCU3501 AI edge computing box offers several advantages, including a high-reliability architecture, robust computing power, and easy deployment. This integrated system is designed for visual quality inspection and safe production in smart factories, providing a vital solution for industries facing challenges in transformation. It serves as a key driving force to overcome existing obstacles.

1. Real Challenges in the Industrial Field

The traditional manufacturing environment is facing multiple pressures: production lines need to accurately identify tiny defects, safe production requires real-time monitoring of personnel behavior, and the status of equipment needs to be visible and controllable. In complex working conditions such as high temperature, dust, and oil pollution, conventional computing devices are difficult to operate stably, and cloud-based solutions are restricted by network latency. Factories urgently need AI computing devices that can process multiple video streams in real-time at the edge and adapt to harsh environments.

2. Hard - Core Strength Designed for Industry

Forlinx Embedded FCU3501 AI edge computing box is based on the Rockchip RK3588J industrial-grade processor, with a built-in NPU computing power of 6 TOPS, and supports the expansion of a 26 TOPS computing power card through the M.2 interface, achieving a total computing power of up to 32 TOPS. This computing power level is sufficient to support a single unit to concurrently process 16 x 1080P industrial camera video streams, meeting the AI processing requirements for real-time video streams in modern factories.

The FCU3501 AI edge computing box features a fanless design that operates effectively in a wide temperature range, from -40°C to +85°C. It is certified by CE and FCC, ensuring reliable performance for 24 hours a day, 7 days a week, even in harsh industrial environments. Its outstanding electromagnetic compatibility allows it to withstand various interferences commonly found in industrial settings, making it ideally suited for such applications.

3. Multiple Values of the Integrated System

The FCU3501 AI edge computing box demonstrates multiple application values in smart factories:

Visual quality inspection on production lines: It can access multiple industrial cameras through dual Gigabit Ethernet and connect additional auxiliary cameras through the USB 3.0 interface. Its powerful computing power analyzes video streams in real - time to detect product defects. At the same time, it can read trigger signals from sensors on the production line through the RS - 485 interface to achieve precise snapshotting.

Equipment status monitoring and early warning: The DI interface can obtain the on - off status or alarm signals of equipment, and the DO interface can control audible and visual alarms. The RS - 232/RS - 485 interface can be used to read the readings of specific industrial instruments. Analysis results and alarms can be wirelessly transmitted to the cloud management platform through the 4G/5G module.

Local monitoring and debugging: The on - site HDMI interface can be connected to a large display screen to display analysis results and monitoring images in real - time. When engineers conduct on - site maintenance, they can perform in - depth system debugging through the DEBUG interface or use WiFi/ Bluetooth for convenient wireless connection and configuration.

Topology Diagram

4. Advantages of the Edge - Cloud Collaborative Architecture

Forlinx Embedded FCU3501 AI edge computing box uses an ''edge-cloud'' collaborative architecture. It performs real-time analysis locally and only uploads structured data and alarm events, significantly reducing bandwidth pressure. This architecture not only ensures real-time performance but also realizes efficient data flow, building a complete digital foundation for factories.

5. Scalable AI Edge Computing Box for the Future

The computing power design of FCU3501 AI edge computing box shows remarkable forward - looking architecture thinking. As the complexity of AI models grows or if more video streams need to be processed, users have the option to upgrade their computing power from 6 TOPS to 32 TOPS by adding an accelerator card. This modular design, which offers "guaranteed basic computing power with the ability to expand for additional value," not only extends the lifecycle of the hardware but also lowers the trial-and-error costs associated with enterprise intelligent transformation.

Today, the FCU3501 AI edge computing box is enhancing production safety with its industrial-grade reliability. It accelerates the adoption of AI through its plug-and-play deployment advantage, while continuously helping manufacturing enterprises build their intelligent competitiveness for the future.