100g Acceleration, 2000Hz Frequency—Exploring the Extreme Vibration Reliability Test of Forlinx Embedded

From the moment an embedded development board leaves the factory until it is put into use, it faces not only complex data-processing tasks but also potential challenges such as severe jolts during long-distance transportation and high-frequency vibrations during operation. So, how to ensure that the board can still operate stably in such extreme environments?

Forlinx Embedded performs vibration and shock tests in its physical environment laboratory. Before the products leave the factory, they are subjected to simulations of harsh environments and undergo rigorous ''brutal tests'' to ensure the reliability of the product.

1. The ''Vibration Marathon'' from 12Hz to 2000Hz

Imagine an embedded board that may experience the bumps of a truck, the swaying of a ship, and finally be installed in a high-speed running device. It faces vibrations of different frequencies throughout its entire lifecycle. The vibration test is a concentrated simulation of these scenarios.

Forlinx Embedded adopts strict test standards to ensure the accuracy and effectiveness of the test results.

Forlinx Embedded's professional vibration table can achieve vibration frequencies ranging from 2Hz to 2000Hz. The amplitude and frequency range for sinusoidal vibration tests is typically set between 2 and 500 Hz, depending on the product form and application scenario. This range encompasses most vibration sources encountered in common transportation and usage contexts. Whether it involves the low-frequency vibrations produced by a truck engine or the high-frequency resonance of a device motor, both generally fall within this frequency range.

The high-frequency vibration in the vibration test is almost invisible to the naked eye.

The vibration table can also achieve a maximum vibration acceleration of 981 m/s², equivalent to subjecting the tested product to 100 times the acceleration due to gravity. Moreover, the vibration covers three orthogonal directions (testing in the X, Y, and Z directions respectively) to comprehensively test its structural endurance.

Through such tests, engineers can find out which solder joints of the product are prone to cracking, which connectors may become loose, and which components will resonate… Discovering these problems in advance means that the product will not be easily damaged or fail due to vibrations in actual use.

Next, let's take a look at the specific process of the vibration test.

First, please verify the structure and functional performance of the test sample to make sure that the tested product is in good condition. Then, set the vibration parameters according to the standards based on the application scenario, such as frequency range, amplitude, acceleration, vibration direction, number of cycles, etc. After that, fix the embedded board on the vibration table and generate simulated vibrations through the vibration table.

During the vibration process, the vibration table will utilize sensors to monitor in real-time whether the vibration curve meets the specified requirements, detects any resonance phenomena, and verifies if the parameters exceed the defined limits. Additionally, it will track the real-time performance of the embedded board, assessing whether its functions operate normally and whether the indicators show any decline. This evaluation is essential for determining the stability and reliability of the board.

After the test, engineers will observe and verify the product's appearance, structure, and functional performance indicators to determine if it meets the experimental requirements.

Additionally, based on the user's application scenario, the vibration platform can also be utilized to perform impact and collision tests to verify whether the product meets the design requirements.

Forlinx Embedded's vibration test report

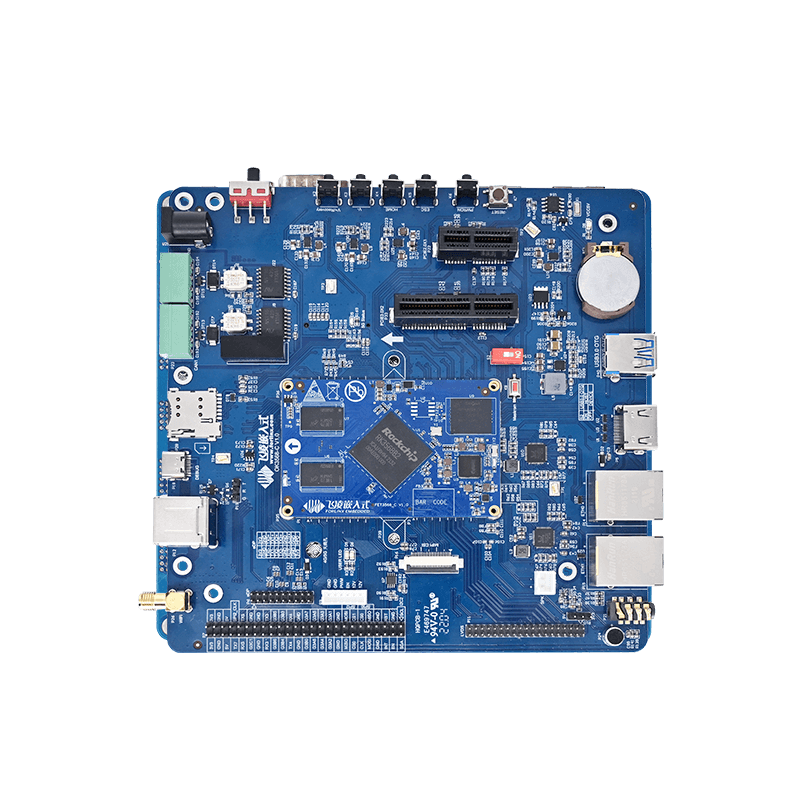

The above-tested product is the OK3506J-C development board.

2. Harsh Tests for Reliable Quality

For Forlinx Embedded, conducting these rigorous tests on products represents a serious commitment to ensuring product quality. In key fields such as industrial control and transportation, any hardware failure can cause serious consequences. Through rigorous vibration testing, Forlinx ensures that even in extreme physical environments, the main control products' systems can operate safely or shut down properly.

Different from consumer products, many embedded devices need to run continuously for several years after installation, and the maintenance cost is extremely high. Sufficient physical environment tests in the early stage significantly reduce the on-site failure rate.

From temperature-controlled computer rooms to vibration-prone vehicle environments, the application scenarios for modern embedded devices are increasingly complex, ranging from stationary servers to mobile robots. Comprehensive physical tests ensure the wide adaptability of the products.

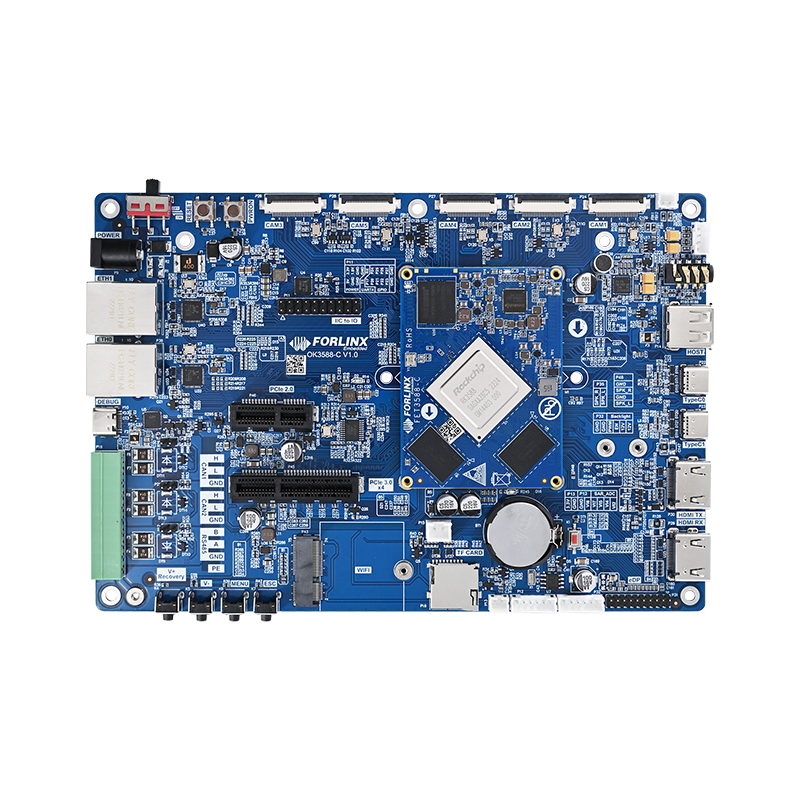

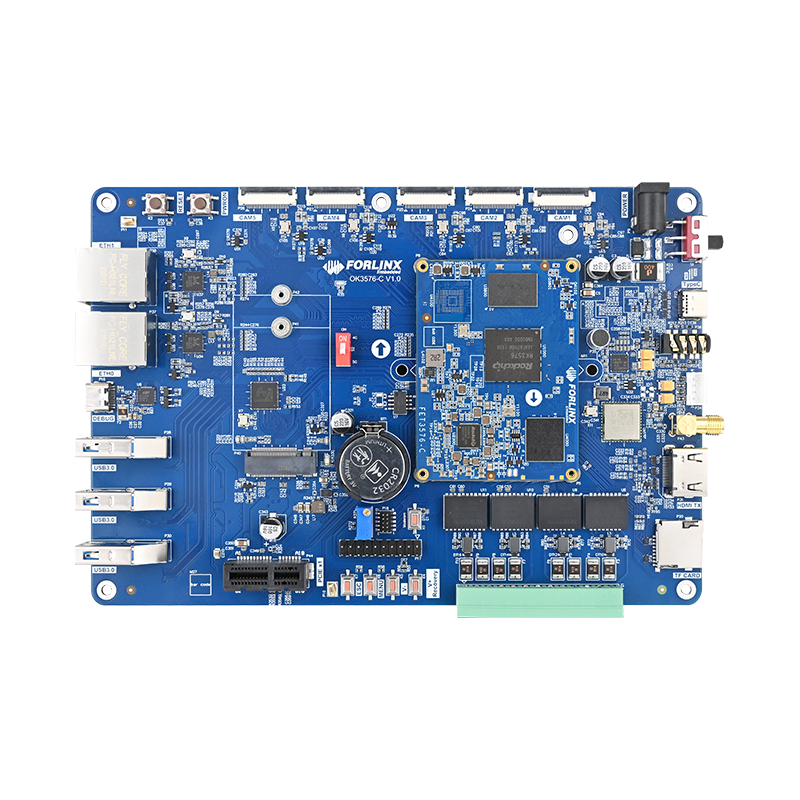

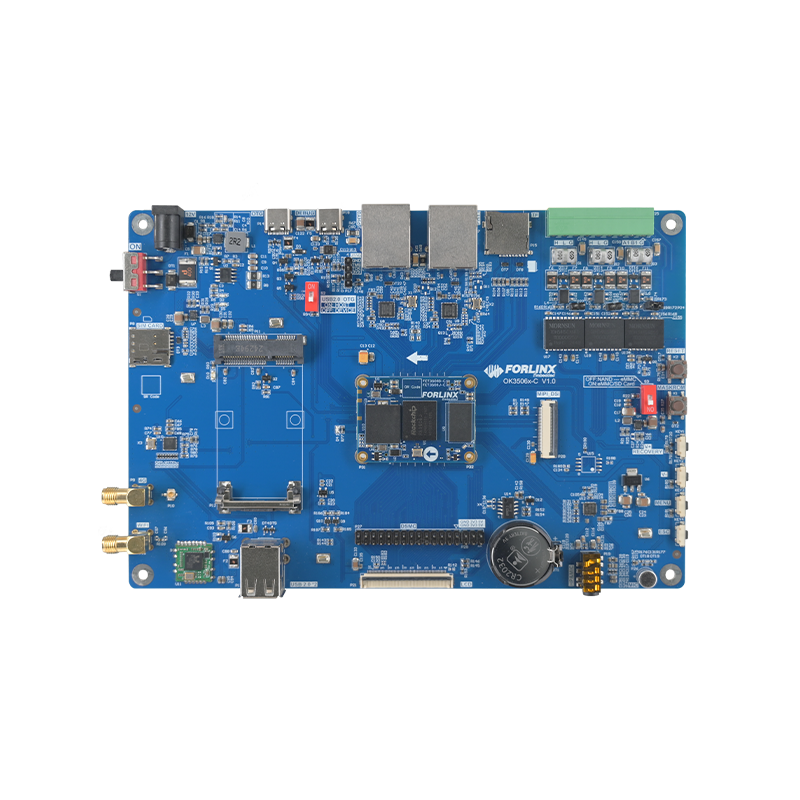

Forlinx Embedded has successfully passed harsh vibration tests on several of its products, including the OK3588-C development board, OK3576-C development board, OK3568-C development board, OK3562-C development board, OK3506-C development board, OK3506-S development board, OK536-C development board, and OKA40i-C development board. In the future, additional products will undergo vibration testing, and test reports will be issued to ensure a more stable and reliable guarantee for customers.

3. Conclusion

In Forlinx Embedded's physical environment laboratory, the activation of the vibration table represents a stringent evaluation of product quality. While the vibration test may seem harsh, it serves as a vital link between the controlled environment of the laboratory and the complex situations products face in real-world applications.

In addition, high-and low-temperature tests, salt-spray tests, drop tests, etc. are all important steps for Forlinx Embedded to verify product reliability, ensuring that the products have stable performance in real environments. It is precisely these "rigorous tests" that ensure smart devices operate stably and reliably in a variety of environments.

The above is an introduction to Forlinx Embedded's vibration test project. More in-depth content will be provided later, so stay tuned.